Lion Electric Investor Presentation Deck

Lion Campus - Battery Plant and Innovation Center

Located in Mirabel, QC, near our existing manufacturing footprint

Completed 100% of the steel structure for the battery plant building

Large 1.6M ft² site with exclusive access to runway for vehicles testing and ample room for future

expansion

■

■

■

8

21700 cylindrical cell-based battery production

Partnership with Ricardo for development of custom module

■

H

■

I

Working with JR Automation (Hitachi) on conception tests for the commercial module production line,

which will first be installed and commissioned at JR Automation's facility, and ultimately transferred to

our Mirabel battery plant

■

L

Innovation Center to focus on R&D: new advancements in performance, range, energy capacity

and the development of innovative products (includes climate testing/battery destruction rooms)

Completion planned for 2023

Retained an advisor to explore a potential sale-leaseback of the battery building

Upcoming Milestones:

Factory acceptance test of the commercial module production line at JRA's facilities

▪ Substantial completion of the battery plant building

Site acceptance test of the commercial module production line at our battery plant

Remain on-track to produce first modules and packs out of the Mirabel battery plant in H2 2022

Rationale

L

■

Completed installation of prototype module line at JR Automation's facility in Troy, Michigan

Produced first prototype pack, which is undergoing testing

Producing additional prototype packs for testing purposes

Projected Cost Savings Through Further

$ Vertical Integration

Significant improvement in Battery Cost

Flexibility to Adapt to Emerging Battery

Technologies

Increased design flexibility and strong

positioning for first-mover advantage with

disruptive technologies (e.g., solid state)

Increasing Supply Alternatives

Management of potential cell shortage, many tier 1

OEM can supply 21700 cell technology

Control Over Battery Design to Optimize

Specifications

Full control over battery specs, optimized for Lion

vehicle platforms, optimal EV weight and balance

including increased onboard kwh

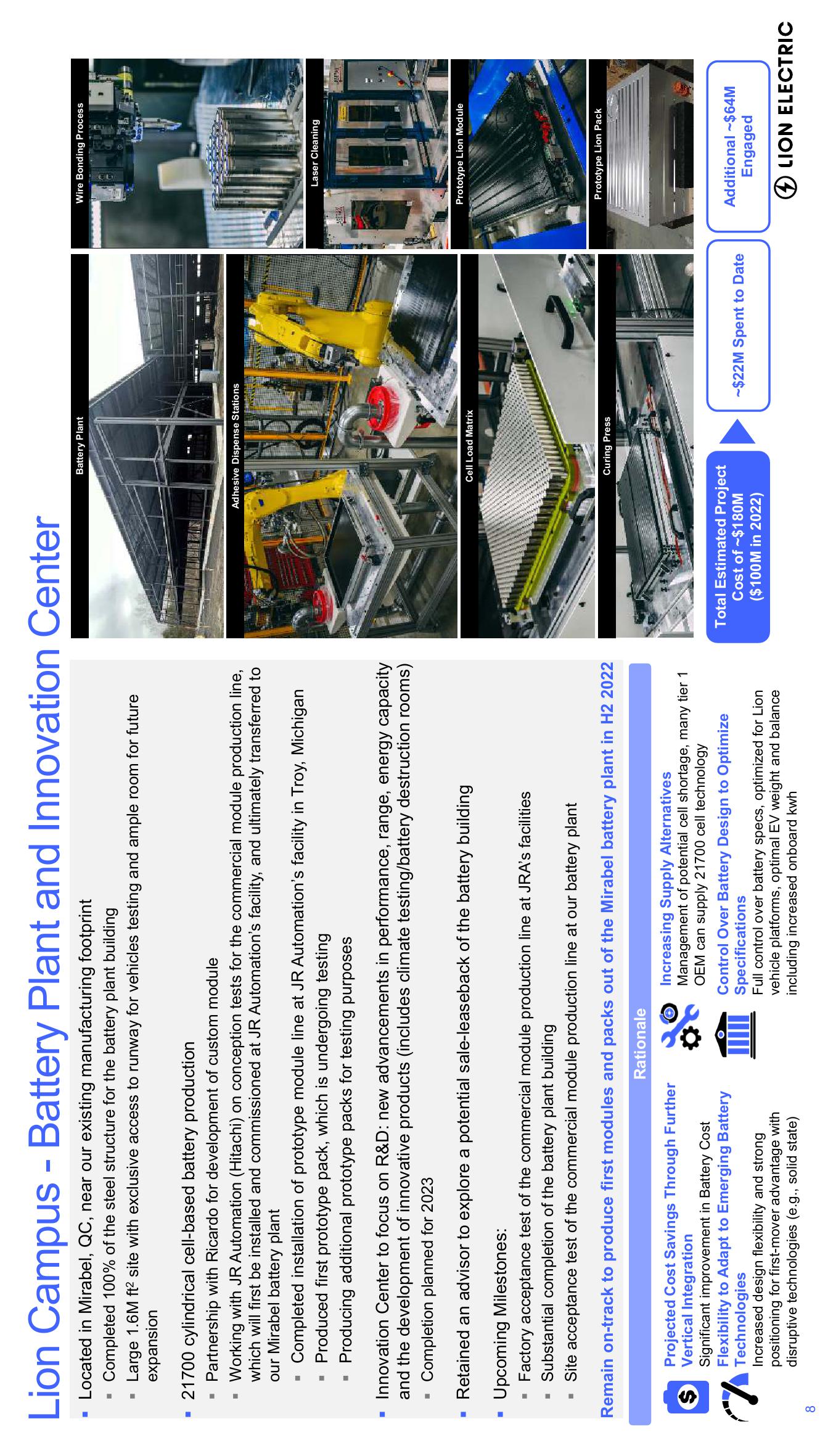

Battery Plant

Adhesive Dispense Stations

Cell Load Matrix

Curing Press

Total Estimated Project

Cost of $180M

($100M in 2022)

Lill m

-$22M Spent to Date

ASETAX

Wire Bonding Process

Laser Cleaning

00

Prototype Lion Module

Prototype Lion Pack

Additional ~$64M

Engaged

JEDE

LION ELECTRICView entire presentation