Solid Power SPAC Presentation Deck

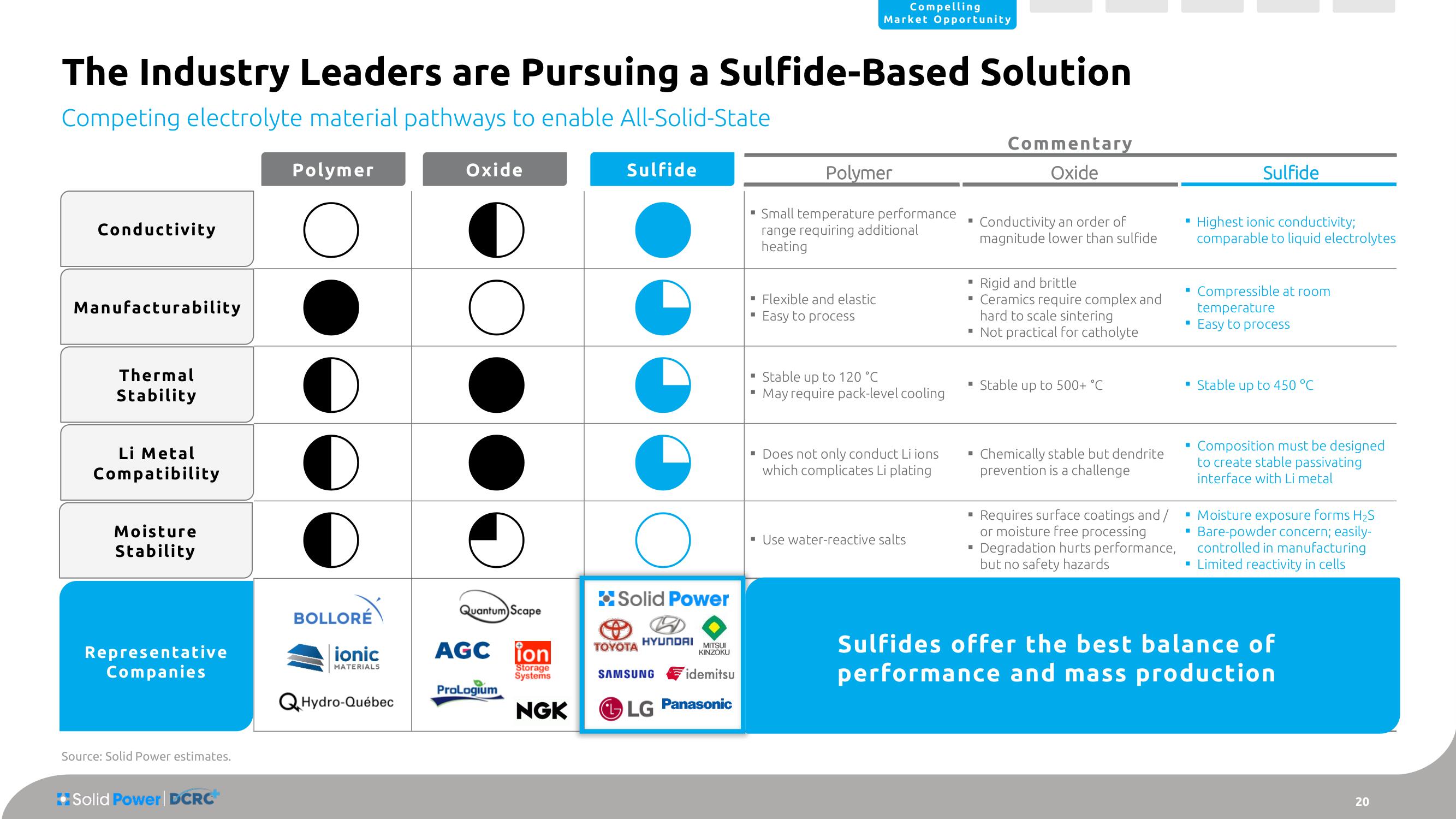

The Industry Leaders are Pursuing a Sulfide-Based Solution

Competing electrolyte material pathways to enable All-Solid-State

Conductivity

Manufacturability

Thermal

Stability

Li Metal

Compatibility

Moisture

Stability

Representative

Companies

Source: Solid Power estimates.

Solid Power | DCRC

Polymer

O

●

●

O

BOLLORÉ

ionic

MATERIALS

QHydro-Québec

Oxide

O

O

●

Quantum Scape

AGC ion

Storage

Systems

ProLogium

NGK

Sulfide

Solid Power

TOYOTA

HYUNDAI MITSUI

KINZOKU

SAMSUNG idemitsu

GLG Panasonic

Compelling

Market Opportunity

▪ Small temperature performance

range requiring additional

heating

■ Flexible and elastic

Easy to process

■

Polymer

"

Stable up to 120 °C

May require pack-level cooling

▪ Does not only conduct Li ions

which complicates Li plating

▪ Use water-reactive salts

■

Commentary

Oxide

Rigid and brittle

Ceramics require complex and

hard to scale sintering

▪ Not practical for catholyte

Conductivity an order of

magnitude lower than sulfide

■

▪ Stable up to 500+ °C

Chemically stable but dendrite

prevention is a challenge

Requires surface coatings and/

or moisture free processing

▪ Degradation hurts performance,

but no safety hazards

■

I

■

■

Sulfide

▪ Stable up to 450 °C

■

Highest ionic conductivity;

comparable to liquid electrolytes

■

Compressible at room

temperature

Easy to process

Moisture exposure forms H₂S

Bare-powder concern; easily-

controlled in manufacturing

▪ Limited reactivity in cells

Composition must be designed

to create stable passivating

interface with Li metal

Sulfides offer the best balance of

performance and mass production

20View entire presentation