Freyr Investor Day Presentation Deck

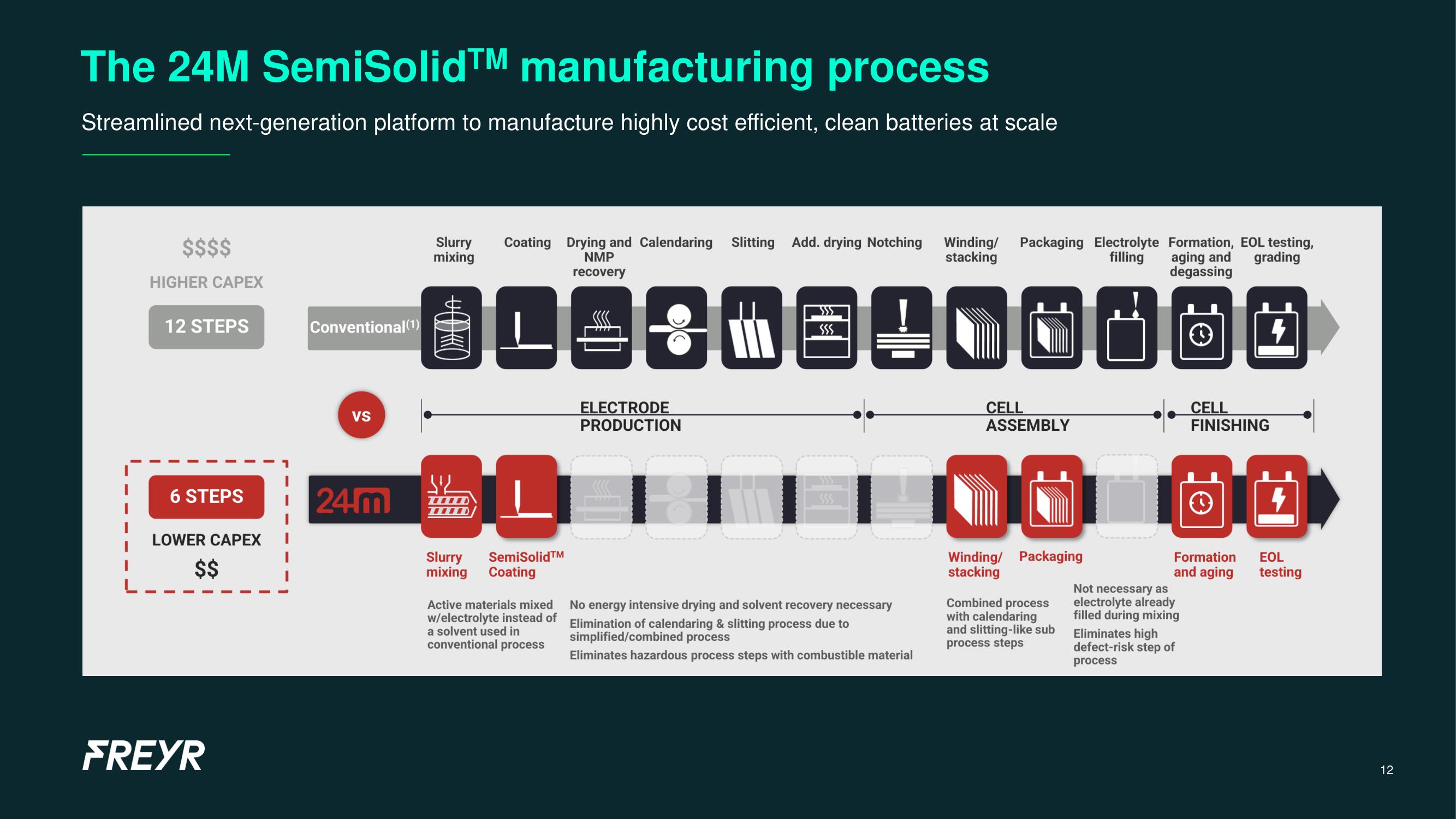

The 24M SemiSolidTM manufacturing process

Streamlined next-generation platform to manufacture highly cost efficient, clean batteries at scale

$$$$

HIGHER CAPEX

12 STEPS

6 STEPS

LOWER CAPEX

$$

FREYR

Conventional (1)

VS

24.m

Slurry

mixing

Coating Drying and Calendaring Slitting Add. drying Notching Winding/ Packaging Electrolyte Formation, EOL testing,

NMP

stacking

filling

aging and

grading

recovery

degassing

AL33=#4TND00

!

312

10

Slurry SemiSolid™

mixing Coating

Active materials mixed

w/electrolyte instead of

a solvent used in

conventional process

ELECTRODE

PRODUCTION

SSS

No energy intensive drying and solvent recovery necessary

Elimination of calendaring & slitting process due to

simplified/combined process

Eliminates hazardous process steps with combustible material

18

CELL

ASSEMBLY

Winding/ Packaging

stacking

Combined process

with calendaring

and slitting-like sub

process steps

CELL

FINISHING

Formation

and aging

Not necessary as

electrolyte already

filled during mixing

Eliminates high

defect-risk step of

process

4

EOL

testing

12View entire presentation