Vale ESG Presentation Deck

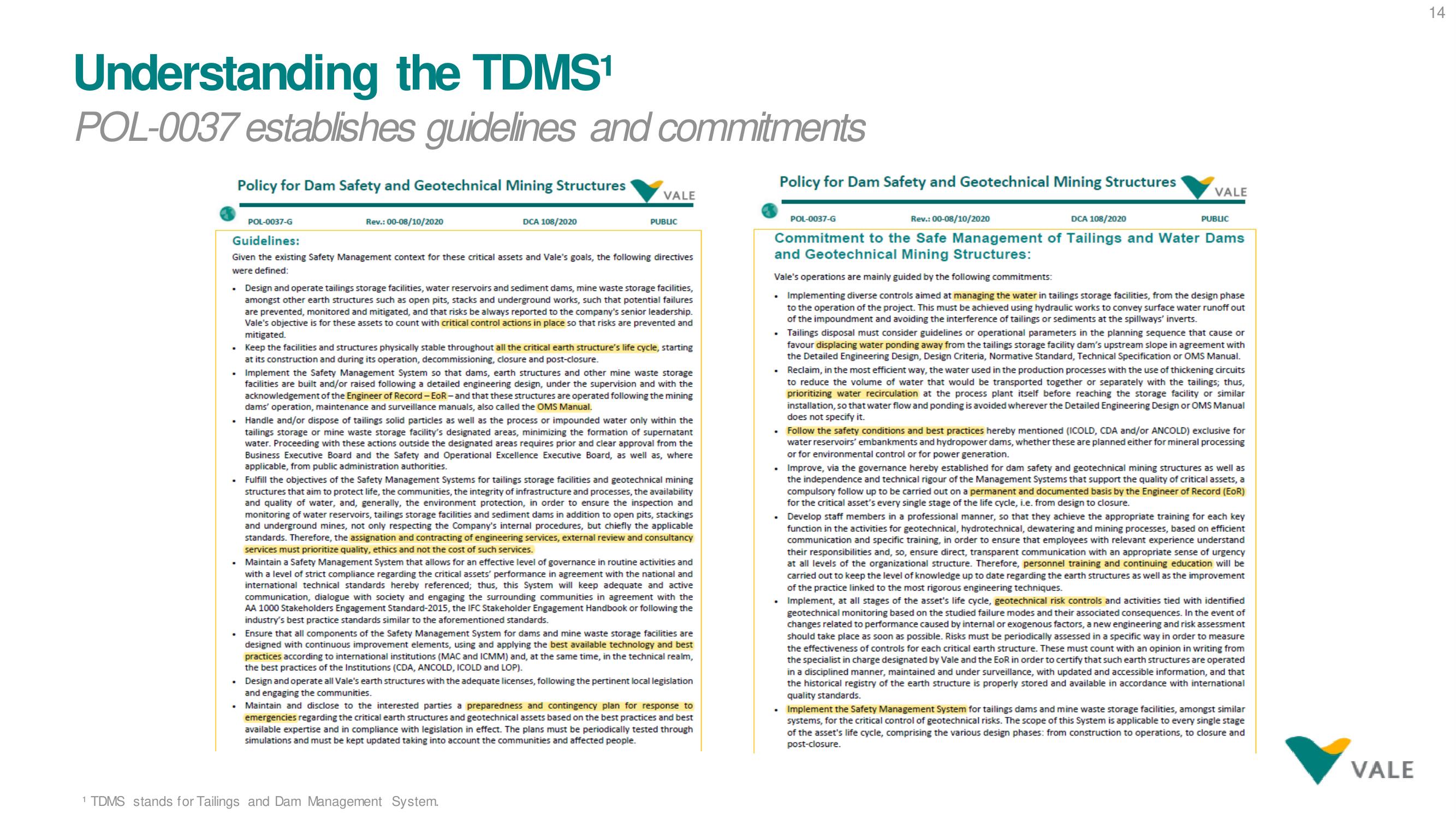

Understanding the TDMS¹

POL-0037 establishes guidelines and commitments

Policy for Dam Safety and Geotechnical Mining Structures

Rev.: 00-08/10/2020

DCA 108/2020

VALE

POL-0037-G

Guidelines:

Given the existing Safety Management context for these critical assets and Vale's goals, the following directives

were defined:

PUBLIC

• Design and operate tailings storage facilities, water reservoirs and sediment dams, mine waste storage facilities,

amongst other earth structures such as open pits, stacks and underground works, such that potential failures

are prevented, monitored and mitigated, and that risks be always reported to the company's senior leadership.

Vale's objective is for these assets to count with critical control actions in place so that risks are prevented and

mitigated.

• Keep the facilities and structures physically stable throughout all the critical earth structure's life cycle, starting

at its construction and during its operation, decommissioning, closure and post-closure.

• Implement the Safety Management System so that dams, earth structures and other mine waste storage

facilities are built and/or raised following a detailed engineering design, under the supervision and with the

acknowledgement of the Engineer of Record - EoR-and that these structures are operated following the mining

dams' operation, maintenance and surveillance manuals, also called the OMS Manual.

• Handle and/or dispose of tailings solid particles as well as the process or impounded water only within the

tailings storage or mine waste storage facility's designated areas, minimizing the formation of supernatant

water. Proceeding with these actions outside the designated areas requires prior and clear approval from the

Business Executive Board and the Safety and Operational Excellence Executive Board, as well as, where

applicable, from public administration authorities.

• Fulfill the objectives of the Safety Management Systems for tailings storage facilities and geotechnical mining

structures that aim to protect life, the communities, the integrity of infrastructure and processes, the availability

and quality of water, and, generally, the environment protection, in order to ensure the inspection and

monitoring of water reservoirs, tailings storage facilities and sediment dams in addition to open pits, stackings

and underground mines, not only respecting the Company's internal procedures, but chiefly the applicable

standards. Therefore, the assignation and contracting of engineering services, external review and consultancy

services must prioritize quality, ethics and not the cost of such services.

• Maintain a Safety Management System that allows for an effective level of governance in routine activities and

with a level of strict compliance regarding the critical assets' performance in agreement with the national and

international technical standards hereby referenced; thus, this System will keep adequate and active

communication, dialogue with society and engaging the surrounding communities in agreement with the

AA 1000 Stakeholders Engagement Standard-2015, the IFC Stakeholder Engagement Handbook or following the

industry's best practice standards similar to the aforementioned standards.

• Ensure that all components of the Safety Management System for dams and mine waste storage facilities are

designed with continuous improvement elements, using and applying the best available technology and best

practices according to international institutions (MAC and ICMM) and, at the same time, in the technical realm,

the best practices of the Institutions (CDA, ANCOLD, ICOLD and LOP).

1 TDMS stands for Tailings and Dam Management System.

• Design and operate all Vale's earth structures with the adequate licenses, following the pertinent local legislation

and engaging the communities.

• Maintain and disclose to the interested parties a preparedness and contingency plan for response to

emergencies regarding the critical earth structures and geotechnical assets based on the best practices and best

available expertise and in compliance with legislation in effect. The plans must be periodically tested through

simulations and must be kept updated taking into account the communities and affected people.

Policy for Dam Safety and Geotechnical Mining Structures

POL-0037-G

Rev.: 00-08/10/2020

PUBLIC

DCA 108/2020

Commitment to the Safe Management of Tailings and Water Dams

and Geotechnical Mining Structures:

Vale's operations are mainly guided by the following commitments:

• Implementing diverse controls aimed at managing the water in tailings storage facilities, from the design phase

to the operation of the project. This must be achieved using hydraulic works to convey surface water runoff out

of the impoundment and avoiding the interference of tailings or sediments at the spillways' inverts.

VALE

• Tailings disposal must consider guidelines or operational parameters in the planning sequence that cause or

favour displacing water ponding away from the tailings storage facility dam's upstream slope in agreement with

the Detailed Engineering Design, Design Criteria, Normative Standard, Technical Specification or OMS Manual.

.

.

Reclaim, in the most efficient way, the water used in the production processes with the use of thickening circuits

to reduce the volume of water that would be transported together or separately with the tailings; thus,

prioritizing water recirculation at the process plant itself before reaching the storage facility or similar

installation, so that water flow and ponding is avoided wherever the Detailed Engineering Design or OMS Manual

does not specify it.

Follow the safety conditions and best practices hereby mentioned (ICOLD, CDA and/or ANCOLD) exclusive for

water reservoirs' embankments and hydropower dams, whether these are planned either for mineral processing

or for environmental control or for power generation.

• Improve, via the governance hereby established for dam safety and geotechnical mining structures as well as

the independence and technical rigour of the Management Systems that support the quality of critical assets, a

compulsory follow up to be carried out on a permanent and documented basis by the Engineer of Record (EoR)

for the critical asset's every single stage of the life cycle, i.e. from design to closure.

• Develop staff members in a professional manner, so that they achieve the appropriate training for each key

function in the activities for geotechnical, hydrotechnical, dewatering and mining processes, based on efficient

communication and specific training, in order to ensure that employees with relevant experience understand

their responsibilities and, so, ensure direct, transparent communication with an appropriate sense of urgency

at all levels of the organizational structure. Therefore, personnel training and continuing education will be

carried out to keep the level of knowledge up to date regarding the earth structures as well as the improvement

of the practice linked to the most rigorous engineering techniques.

• Implement, at all stages of the asset's life cycle, geotechnical risk controls and activities tied with identified

geotechnical monitoring based on the studied failure modes and their associated consequences. In the event of

changes related to performance caused by internal or exogenous factors, a new engineering and risk assessment

should take place as soon as possible. Risks must be periodically assessed in a specific way in order to measure

the effectiveness of controls for each critical earth structure. These must count with an opinion in writing from

the specialist in charge designated by Vale and the EoR in order to certify that such earth structures are operated

in a disciplined manner, maintained and under surveillance, with updated and accessible information, and that

the historical registry of the earth structure is properly stored and available in accordance with international

quality standards.

• Implement the Safety Management System for tailings dams and mine waste storage facilities, amongst similar

systems, for the critical control of geotechnical risks. The scope of this System is applicable to every single stage

of the asset's life cycle, comprising the various design phases: from construction to operations, to closure and

post-closure.

VALE

14View entire presentation