The Global Solar Photovoltaic Supply Chain and Bottom-UP Cost Model Results

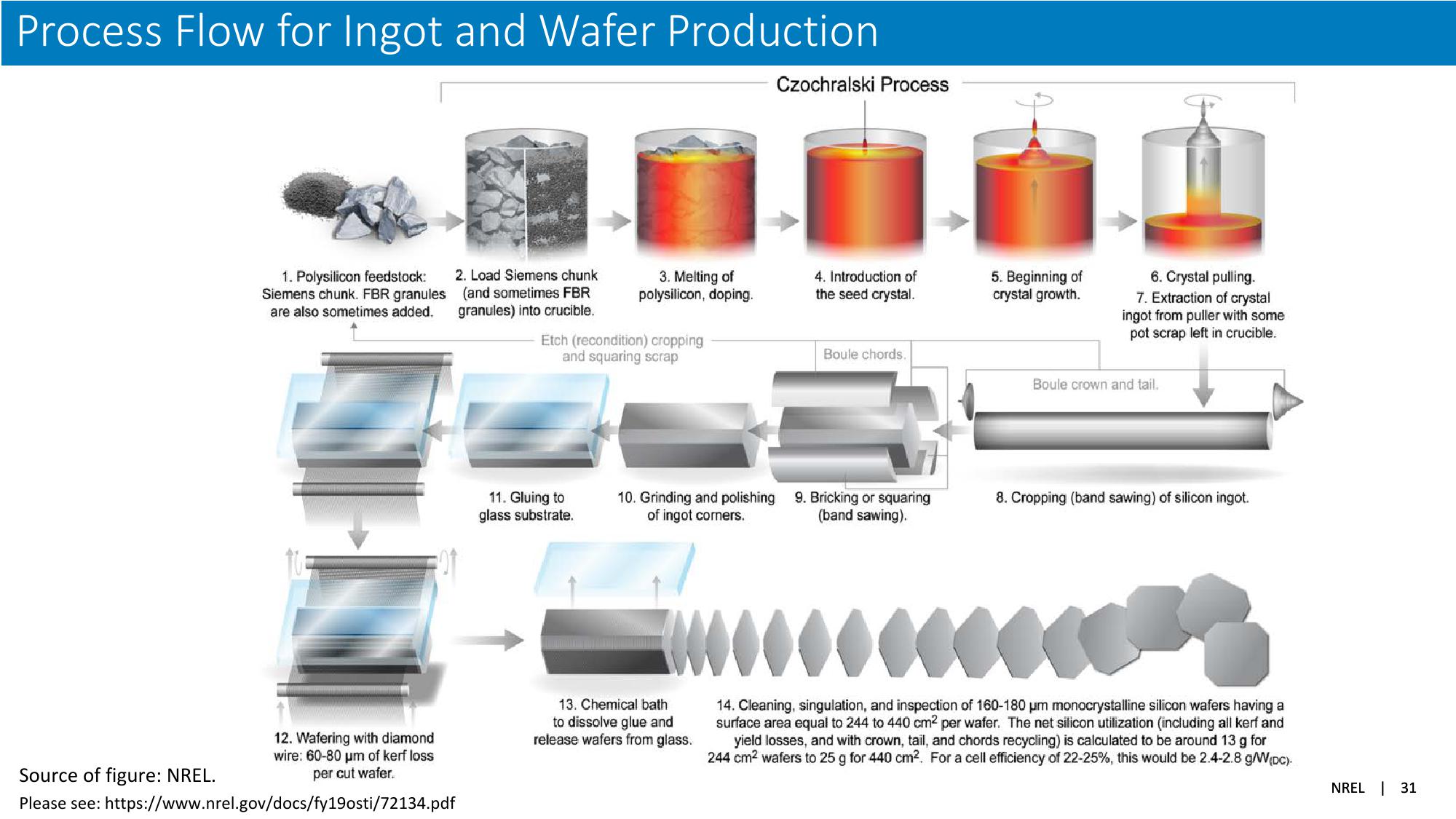

Process Flow for Ingot and Wafer Production

Czochralski Process

1. Polysilicon feedstock:

Siemens chunk. FBR granules

are also sometimes added.

2. Load Siemens chunk

(and sometimes FBR

granules) into crucible.

3. Melting of

polysilicon, doping.

Etch (recondition) cropping

and squaring scrap

10:

12. Wafering with diamond

Source of figure: NREL.

wire: 60-80 μm of kerf loss

per cut wafer.

Please see: https://www.nrel.gov/docs/fy19osti/72134.pdf

4. Introduction of

the seed crystal.

5. Beginning of

crystal growth.

6. Crystal pulling.

7. Extraction of crystal

ingot from puller with some

pot scrap left in crucible.

Boule chords.

Boule crown and tail.

11. Gluing to

glass substrate.

10. Grinding and polishing 9. Bricking or squaring

of ingot corners.

(band sawing).

8. Cropping (band sawing) of silicon ingot.

13. Chemical bath

to dissolve glue and

release wafers from glass.

14. Cleaning, singulation, and inspection of 160-180 μm monocrystalline silicon wafers having a

surface area equal to 244 to 440 cm2 per wafer. The net silicon utilization (including all kerf and

yield losses, and with crown, tail, and chords recycling) is calculated to be around 13 g for

244 cm² wafers to 25 g for 440 cm². For a cell efficiency of 22-25%, this would be 2.4-2.8 g/W(pc).

NREL 31View entire presentation