Optimizing Design and Controls for Thermal Energy Storage

Finite Difference Model

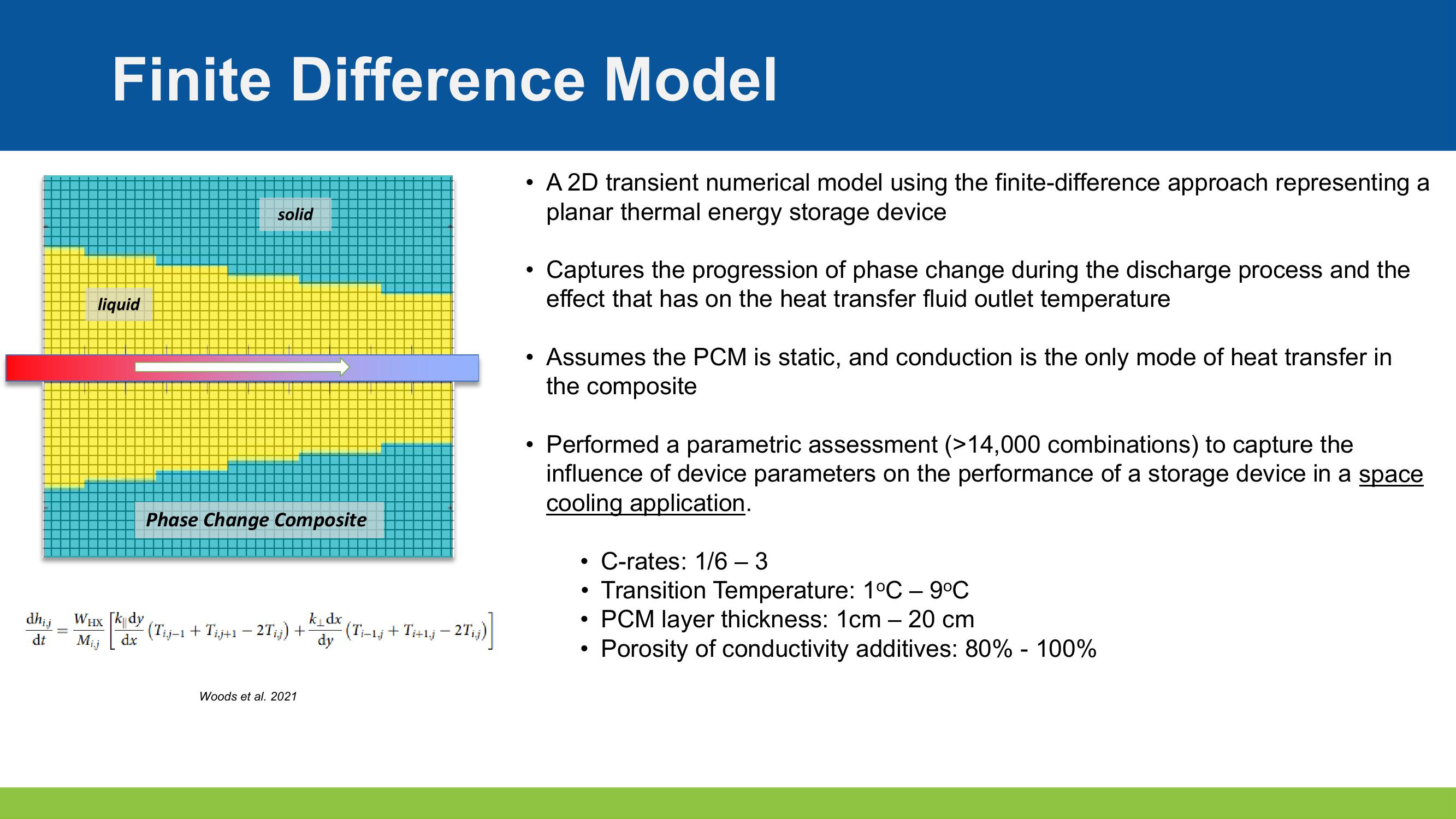

liquid

solid

Phase Change Composite

•

•

A 2D transient numerical model using the finite-difference approach representing a

planar thermal energy storage device.

Captures the progression of phase change during the discharge process and the

effect that has on the heat transfer fluid outlet temperature

Assumes the PCM is static, and conduction is the only mode of heat transfer in

the composite

• Performed a parametric assessment (>14,000 combinations) to capture the

influence of device parameters on the performance of a storage device in a space

cooling application.

•

C-rates: 1/6 - 3

Transition Temperature: 1°C -9°C

PCM layer thickness: 1cm - 20 cm

·

dhij

WHX [k dy

kdx

dt

Mi.j

dx

(Tij-1+ Tij+1-2Ti,j) +

(Ti−1,j + Ti+1j − 2Tij)

-

dy

•

Porosity of conductivity additives: 80% - 100%

Woods et al. 2021View entire presentation