Solid Power SPAC Presentation Deck

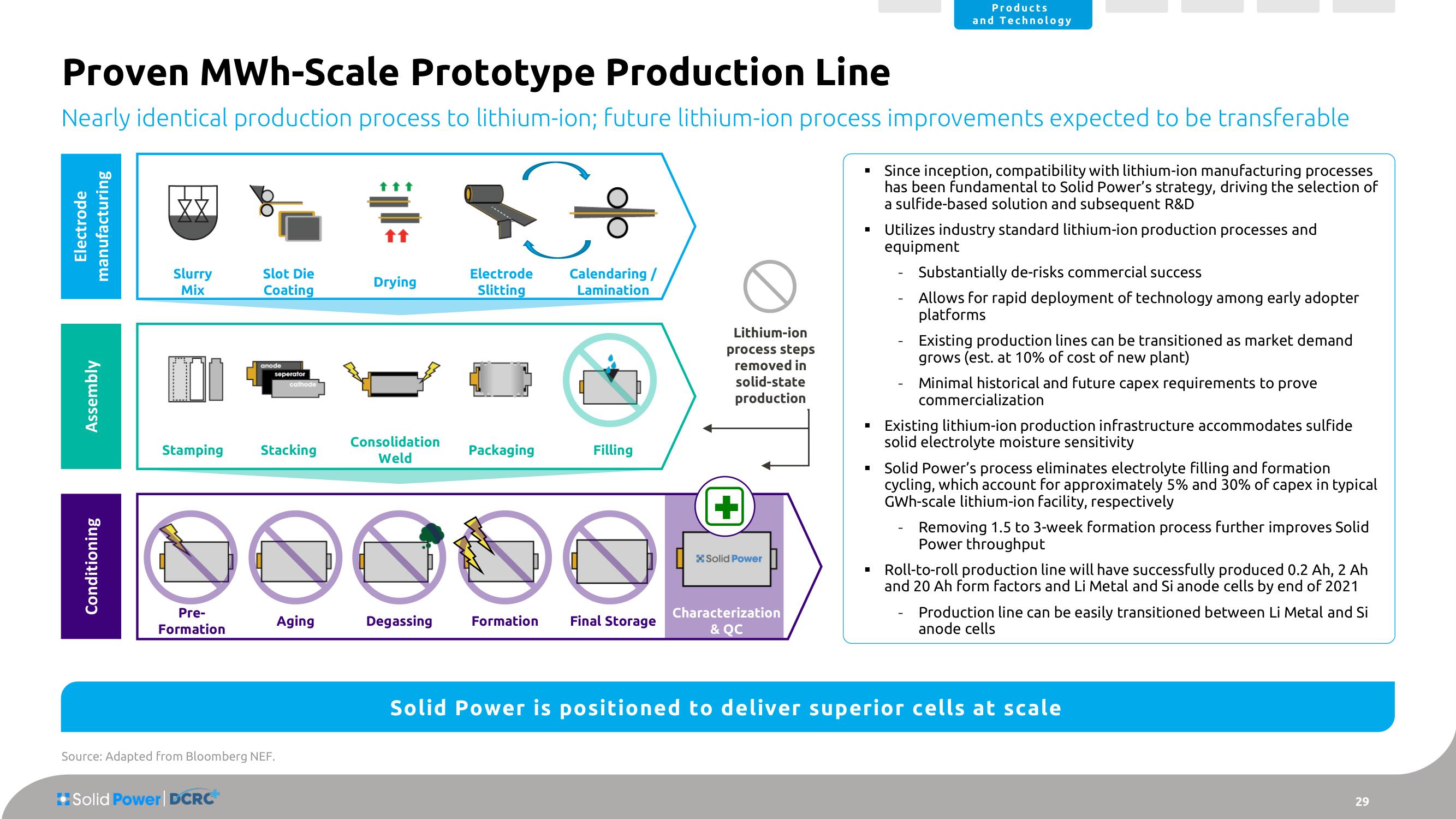

Proven MWh-Scale Prototype Production Line

Nearly identical production process to lithium-ion; future lithium-ion process improvements expected to be transferable

Electrode

manufacturing

Assembly

Conditioning

XX

AA

Slurry

Mix

000

Stamping

Pre-

Formation

Slot Die

Coating

Solid Power DCRC

anode

seperator

cathode

Stacking

Source: Adapted from Bloomberg NEF.

ttt

Drying

Consolidation

Weld

Electrode Calendaring /

Slitting

Lamination

Packaging

Filling

Aging Degassing Formation Final Storage

Lithium-ion

process steps

removed in

solid-state

production

+

Solid Power

Characterization

& QC

Products

and Technology

▪ Since inception, compatibility with lithium-ion manufacturing processes

has been fundamental to Solid Power's strategy, driving the selection of

a sulfide-based solution and subsequent R&D

■ Utilizes industry standard lithium-ion production processes and

equipment

·

-

Substantially de-risks commercial success

Allows for rapid deployment of technology among early adopter

platforms

Existing production lines can be transitioned as market demand

grows (est. at 10% of cost of new plant)

Minimal historical and future capex requirements to prove

commercialization

Existing lithium-ion production infrastructure accommodates sulfide

solid electrolyte moisture sensitivity

▪ Solid Power's process eliminates electrolyte filling and formation

cycling, which account for approximately 5% and 30% of capex in typical

GWh-scale lithium-ion facility, respectively

Removing 1.5 to 3-week formation process further improves Solid

Power throughput

Roll-to-roll production line will have successfully produced 0.2 Ah, 2 Ah

and 20 Ah form factors and Li Metal and Si anode cells by end of 2021

Production line can be easily transitioned between Li Metal and Si

anode cells

Solid Power is positioned to deliver superior cells at scale

29View entire presentation