Evercore Investment Banking Pitch Book

SIRE Situation Analysis

Deca Rehydration

Commentary

SIRE's surface site includes a network of natural ponds used

to recapture soda ash lost in processing trona through a

process called deca rehydration

During trona processing, an evaporative crystallizer

technology is employed to refine and reuse soda ash

throughout the purification process. A concentrated

aqueous solution is introduced to maintain the purity and

quality of the refined soda ash product. Run-off from this

stream flows to the facility's pond network

SIRE developed a solution to reduce the capacity of these

ponds and recover purified soda ash crystals (chemically,

sodium carbonate decahydrate) to be used as an

additional feedstock for trona ore during processing

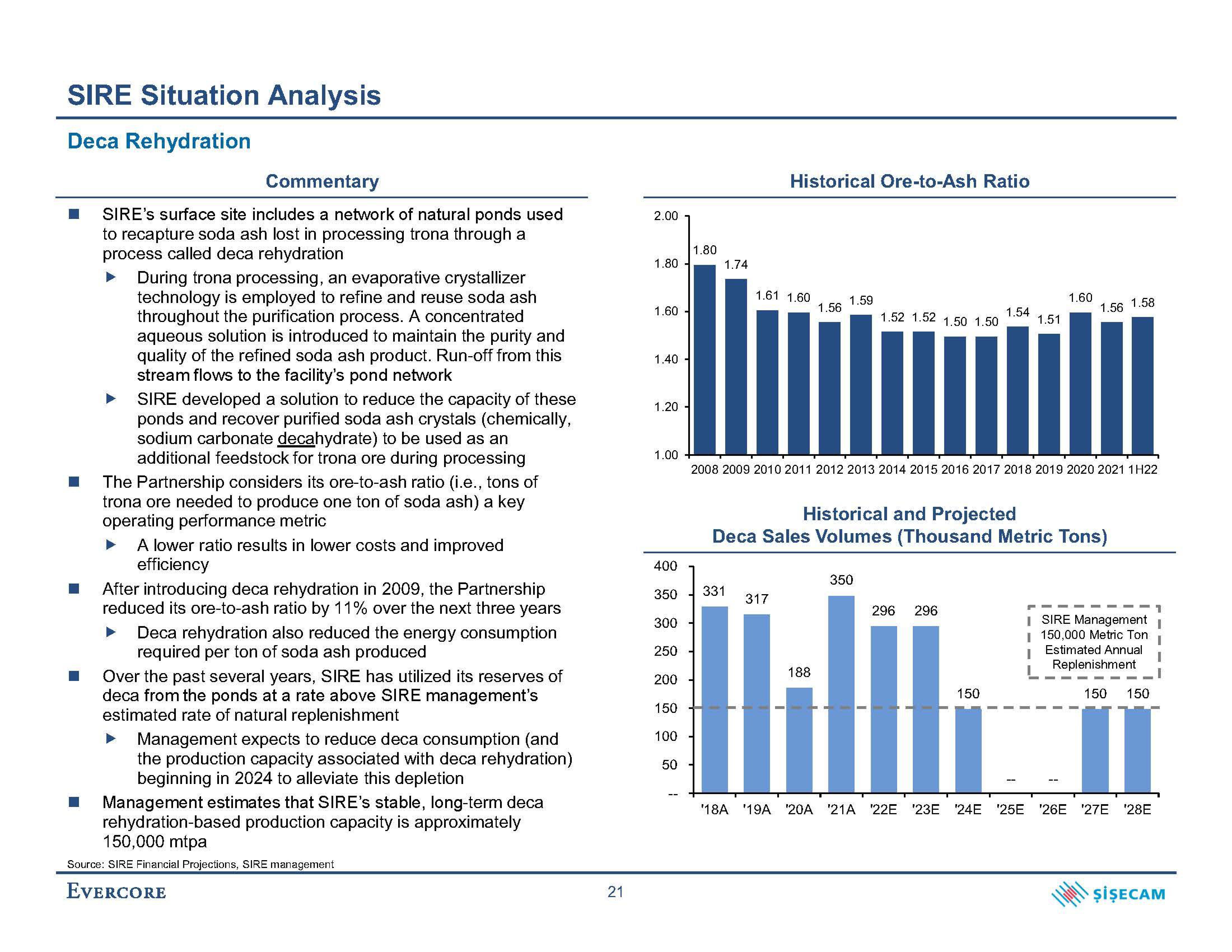

The Partnership considers its ore-to-ash ratio (i.e., tons of

trona ore needed to produce one ton of soda ash) a key

operating performance metric

A lower ratio results in lower costs and improved

efficiency

After introducing deca rehydration in 2009, the Partnership

reduced its ore-to-ash ratio by 11% over the next three years

▶ Deca rehydration also reduced the energy consumption

required per ton of soda ash produced

Over the past several years, SIRE has utilized its reserves of

deca from the ponds at a rate above SIRE management's

estimated rate of natural replenishment

Management expects to reduce deca consumption (and

the production capacity associated with deca rehydration)

beginning in 2024 to alleviate this depletion

Management estimates that SIRE's stable, long-term deca

rehydration-based production capacity is approximately

150,000 mtpa

Source: SIRE Financial Projections, SIRE management

EVERCORE

21

2.00

1.80

1.60

1.40

1.20

1.00

400

350

300

250

200

150

100

50

1.80

1.74

Historical Ore-to-Ash Ratio

1.61 1.60

331

317

1.56

1.59

188

1.52 1.52 1.50 1.50

2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 1H22

350

Historical and Projected

Deca Sales Volumes (Thousand Metric Tons)

1.54

296 296

150

1.51

1.60

1.56 1.58

I

I

ISIRE Management

150,000 Metric Ton

Estimated Annual

Replenishment

150 150

'18A '19A '20A '21A 22E '23E 24E '25E '26E '27E '28E

ŞİŞECAMView entire presentation