Clean Battery Solutions for a Better Planet

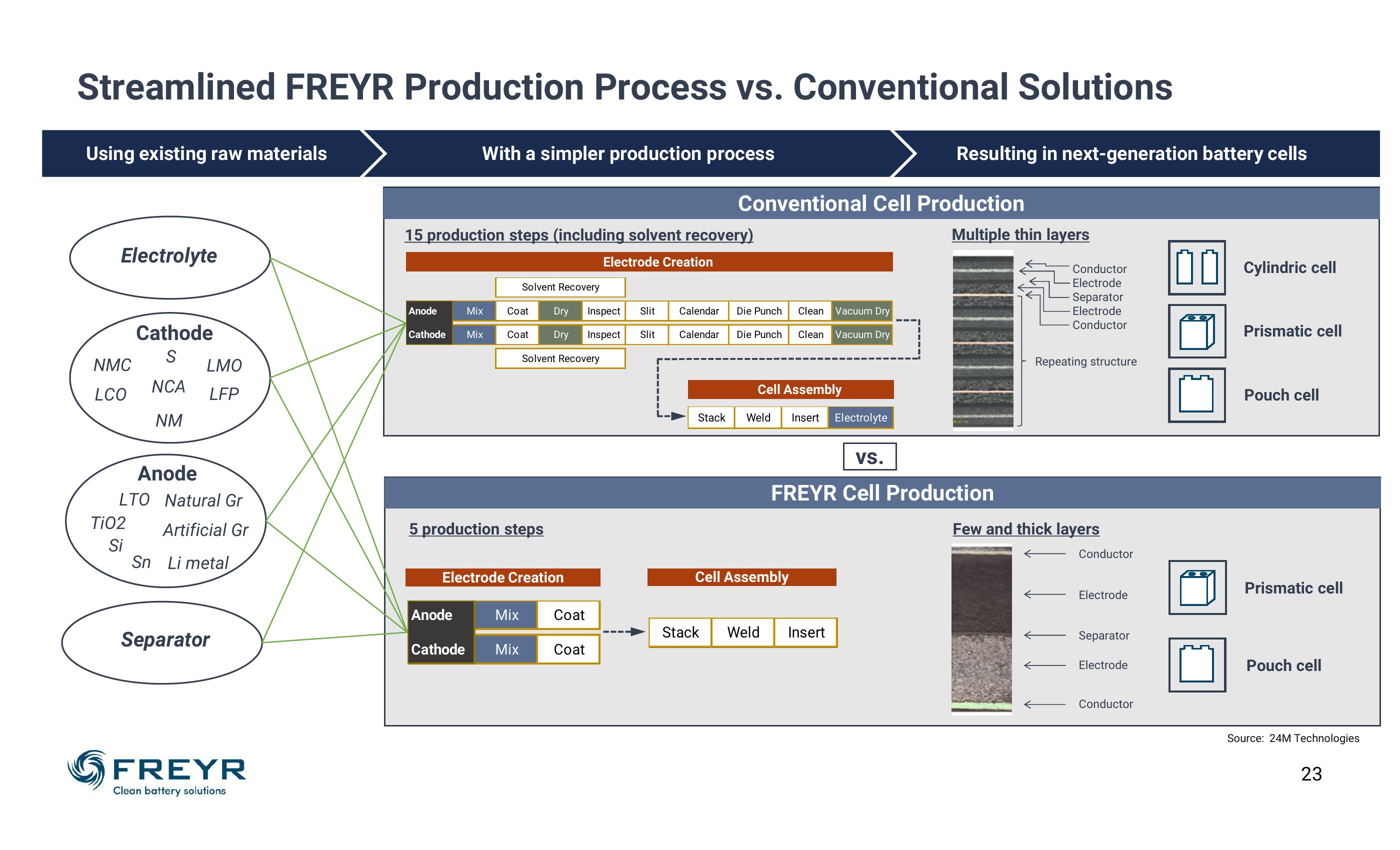

Streamlined FREYR Production Process vs. Conventional Solutions

Using existing raw materials

With a simpler production process

Electrolyte

Cathode

S

NMC

LMO

NCA

LCO

LFP

NM

Anode

LTO Natural Gr

TiO2

Si

Resulting in next-generation battery cells

Conventional Cell Production

15 production steps (including solvent recovery)

Multiple thin layers

Electrode Creation

Conductor

Electrode

☐☐ Cylindric cell

Solvent Recovery

Separator

Anode

Mix

Coat

Dry Inspect

Slit

Calendar

Die Punch

Clean

Cathode

Mix

Coat

Dry Inspect Slit

Calendar

Die Punch

Clean

Vacuum Dry

Vacuum Dry

Electrode

Conductor

Prismatic cell

Solvent Recovery

Repeating structure

Pouch cell

Artificial Gr

5 production steps

Sn Li metal

Separator

FREYR

Clean battery solutions

Cell Assembly

Stack

Weld

Insert Electrolyte

VS.

FREYR Cell Production

Electrode Creation

Cell Assembly

Anode

Mix

Coat

Stack

Weld Insert

Cathode

Mix

Coat

Few and thick layers

Conductor

Prismatic cell

Electrode

Separator

Electrode

Pouch cell

Conductor

Source: 24M Technologies

23View entire presentation