Matterport Results Presentation Deck

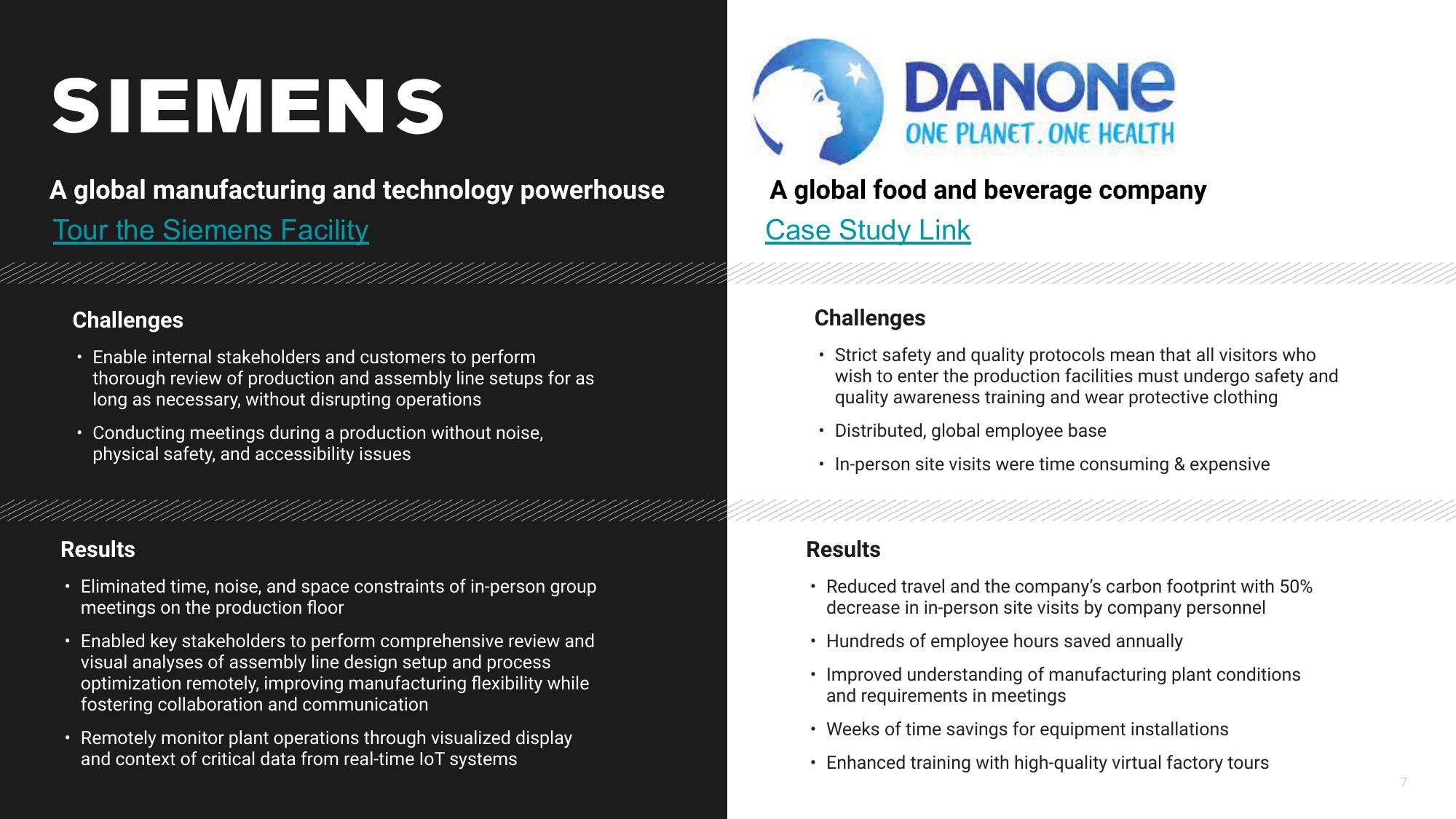

SIEMENS

A global manufacturing and technology powerhouse

Tour the Siemens Facility

Challenges

Enable internal stakeholders and customers to perform

thorough review of production and assembly line setups for as

long as necessary, without disrupting operations

Conducting meetings during a production without noise,

physical safety, and accessibility issues

Results

Eliminated time, noise, and space constraints of in-person group

meetings on the production floor

• Enabled key stakeholders to perform comprehensive review and

visual analyses of assembly line design setup and process

optimization remotely, improving manufacturing flexibility while

fostering collaboration and communication

Remotely monitor plant operations through visualized display

and context of critical data from real-time loT systems

DANONE

ONE PLANET. ONE HEALTH

A global food and beverage company

Case Study Link

Challenges

• Strict safety and quality protocols mean that all visitors who

wish to enter the production facilities must undergo safety and

quality awareness training and wear protective clothing

• Distributed, global employee base

In-person site visits were time consuming & expensive

Results

Reduced travel and the company's carbon footprint with 50%

decrease in in-person site visits by company personnel

Hundreds of employee hours saved annually

Improved understanding of manufacturing plant conditions

and requirements in meetings

• Weeks of time savings for equipment installations

Enhanced training with high-quality virtual factory tours

.View entire presentation