Endeavour Mining Investor Presentation Deck

★

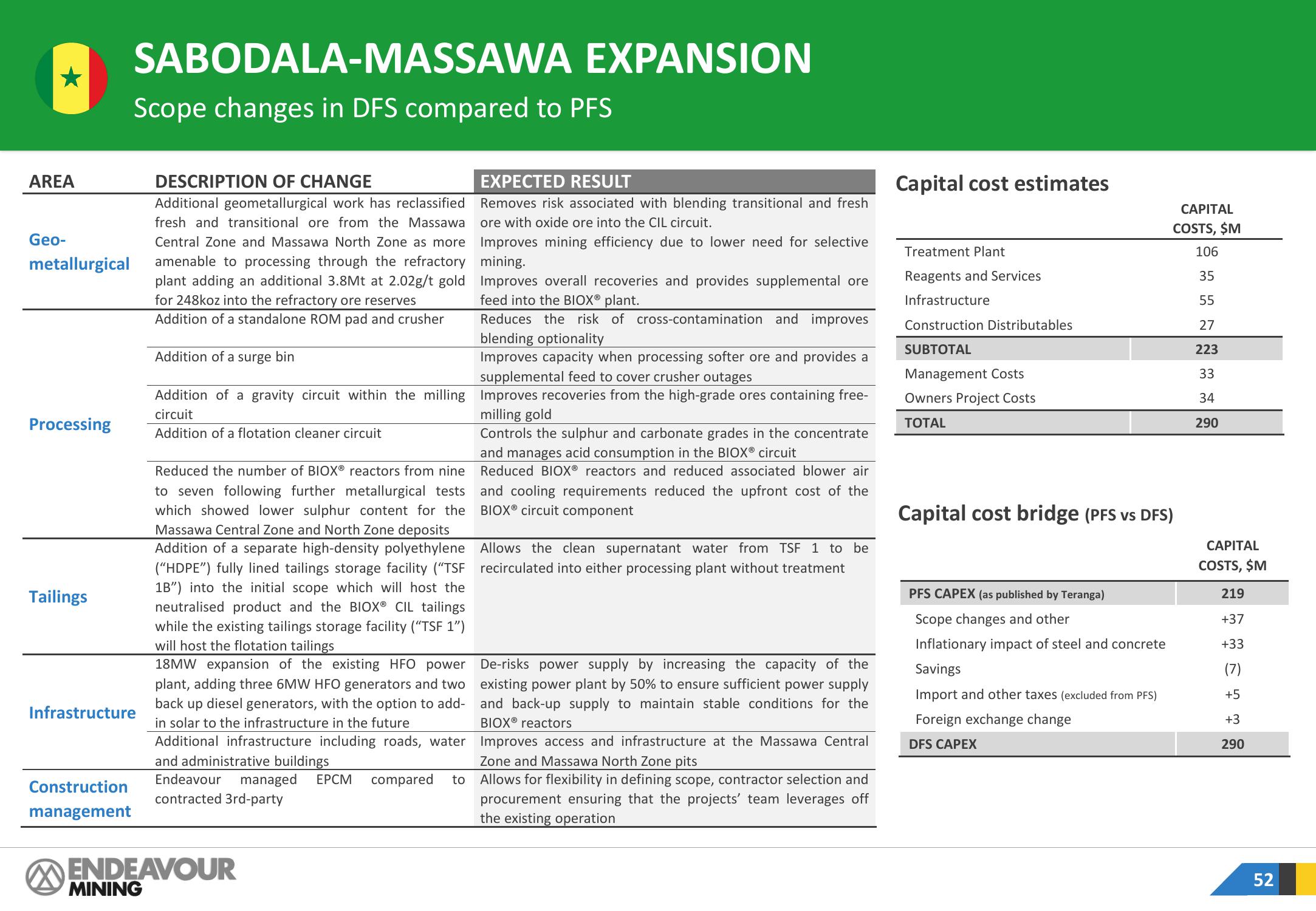

AREA

Geo-

metallurgical

Processing

Tailings

SABODALA-MASSAWA EXPANSION

Scope changes in DFS compared to PFS

Infrastructure

Construction

management

DESCRIPTION OF CHANGE

Additional geometallurgical work has reclassified

fresh and transitional ore from the Massawa

Central Zone and Massawa North Zone as more

amenable to processing through the refractory

plant adding an additional 3.8Mt at 2.02g/t gold

for 248koz into the refractory ore reserves

Addition of a standalone ROM pad and crusher

Addition of a surge bin

MINING

Improves mining efficiency due to lower need for selective

mining.

Improves overall recoveries and provides supplemental ore

feed into the BIOX® plant.

Reduces the risk of cross-contamination and improves

blending optionality

Improves capacity when processing softer ore and provides a

supplemental feed to cover crusher outages

Addition of a gravity circuit within the milling Improves recoveries from the high-grade ores containing free-

circuit

milling gold

Addition of a flotation cleaner circuit

Controls the sulphur and carbonate grades in the concentrate

and manages acid consumption in the BIOX® circuit

Reduced BIOX® reactors and reduced associated blower air

and cooling requirements reduced the upfront cost of the

BIOX® circuit component

Reduced the number of BIOX® reactors from nine

to seven following further metallurgical tests

which showed lower sulphur content for the

Massawa Central Zone and North Zone deposits

Addition of a separate high-density polyethylene

("HDPE") fully lined tailings storage facility ("TSF

1B") into the initial scope which will host the

neutralised product and the BIOX® CIL tailings

while the existing tailings storage facility ("TSF 1")

will host the flotation tailings

18MW expansion of the existing HFO power

plant, adding three 6MW HFO generators and two

back up diesel generators, with the option to add-

in solar to the infrastructure in the future

Additional infrastructure including roads, water

and administrative buildings

Endeavour managed EPCM compared

contracted 3rd-party

ENDEAVOUR

EXPECTED RESULT

Removes risk associated with blending transitional and fresh

ore with oxide ore into the CIL circuit.

to

Allows the clean supernatant water from TSF 1 to be

recirculated into either processing plant without treatment

De-risks power supply by increasing the capacity of the

existing power plant by 50% to ensure sufficient power supply

and back-up supply to maintain stable conditions for the

BIOX® reactors

Improves access and infrastructure at the Massawa Central

Zone and Massawa North Zone pits

Allows for flexibility in defining scope, contractor selection and

procurement ensuring that the projects' team leverages off

the existing operation

Capital cost estimates

Treatment Plant

Reagents and Services

Infrastructure

Construction Distributables

SUBTOTAL

Management Costs

Owners Project Costs

TOTAL

CAPITAL

COSTS, $M

106

35

55

27

223

33

34

290

Capital cost bridge (PFS vs DFS)

PFS CAPEX (as published by Teranga)

Scope changes and other

Inflationary impact of steel and concrete

Savings

Import and other taxes (excluded from PFS)

Foreign exchange change

DFS CAPEX

CAPITAL

COSTS, $M

219

+37

+33

(7)

+5

+3

290

52View entire presentation