Optimizing Design and Controls for Thermal Energy Storage

Parallel Phase Front Approximation Model

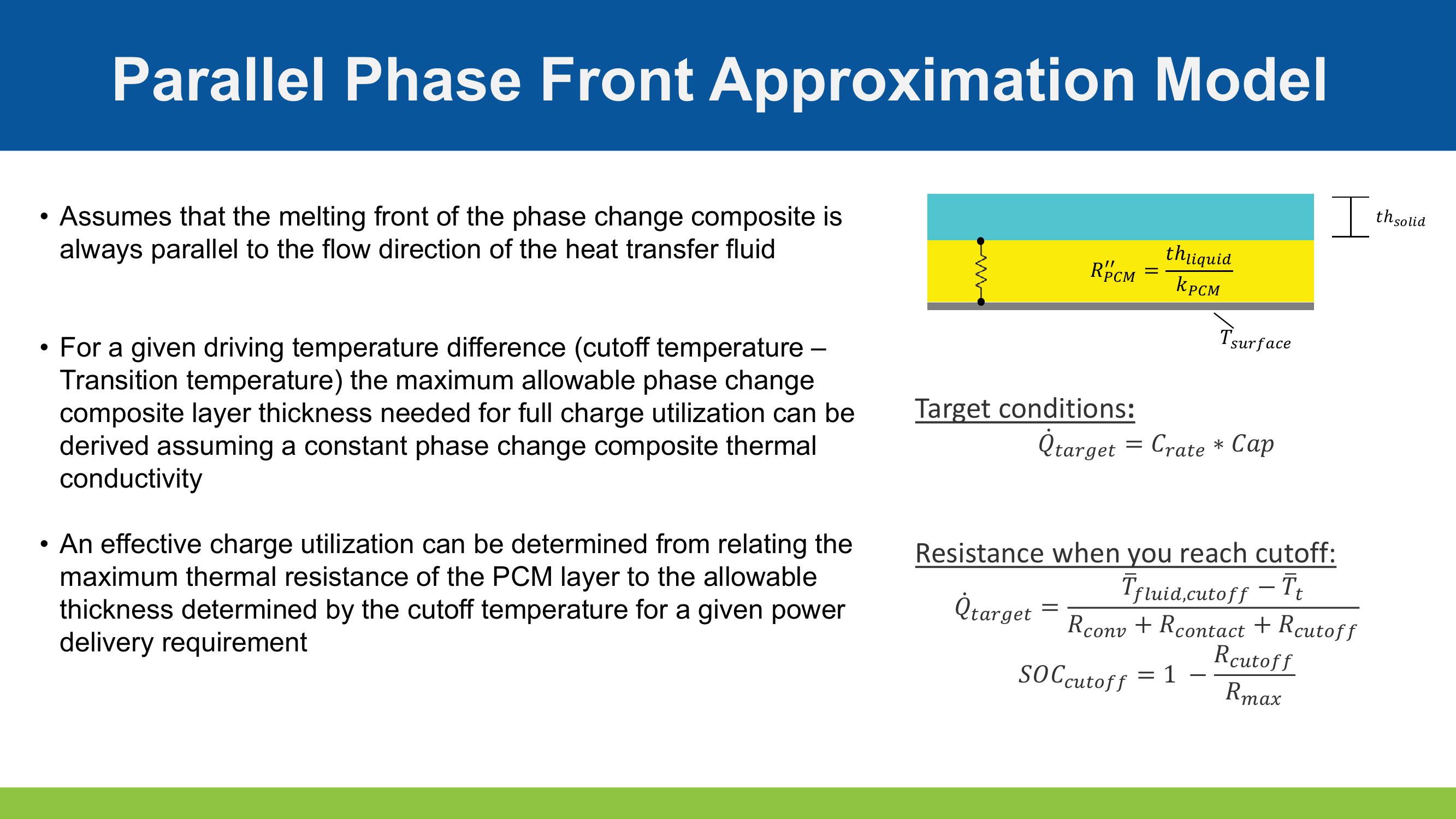

Assumes that the melting front of the phase change composite is

always parallel to the flow direction of the heat transfer fluid

I'

th solid

thliquid

RPCM =

Крсм

surface

• For a given driving temperature difference (cutoff temperature -

Transition temperature) the maximum allowable phase change

composite layer thickness needed for full charge utilization can be

derived assuming a constant phase change composite thermal

conductivity

•

An effective charge utilization can be determined from relating the

maximum thermal resistance of the PCM layer to the allowable

thickness determined by the cutoff temperature for a given power

delivery requirement

Target conditions:

Qtarget = Crate * Cap

Resistance when you reach cutoff:

Qtarget

Tfluid,cutoff - Tt

Rconv + Rcontact + Rcutoff

Rcutoff

SOC cutoff

= 1

-

RmaxView entire presentation