Melrose Investor Day Presentation Deck

Melrose

Buy

Improve

Sell

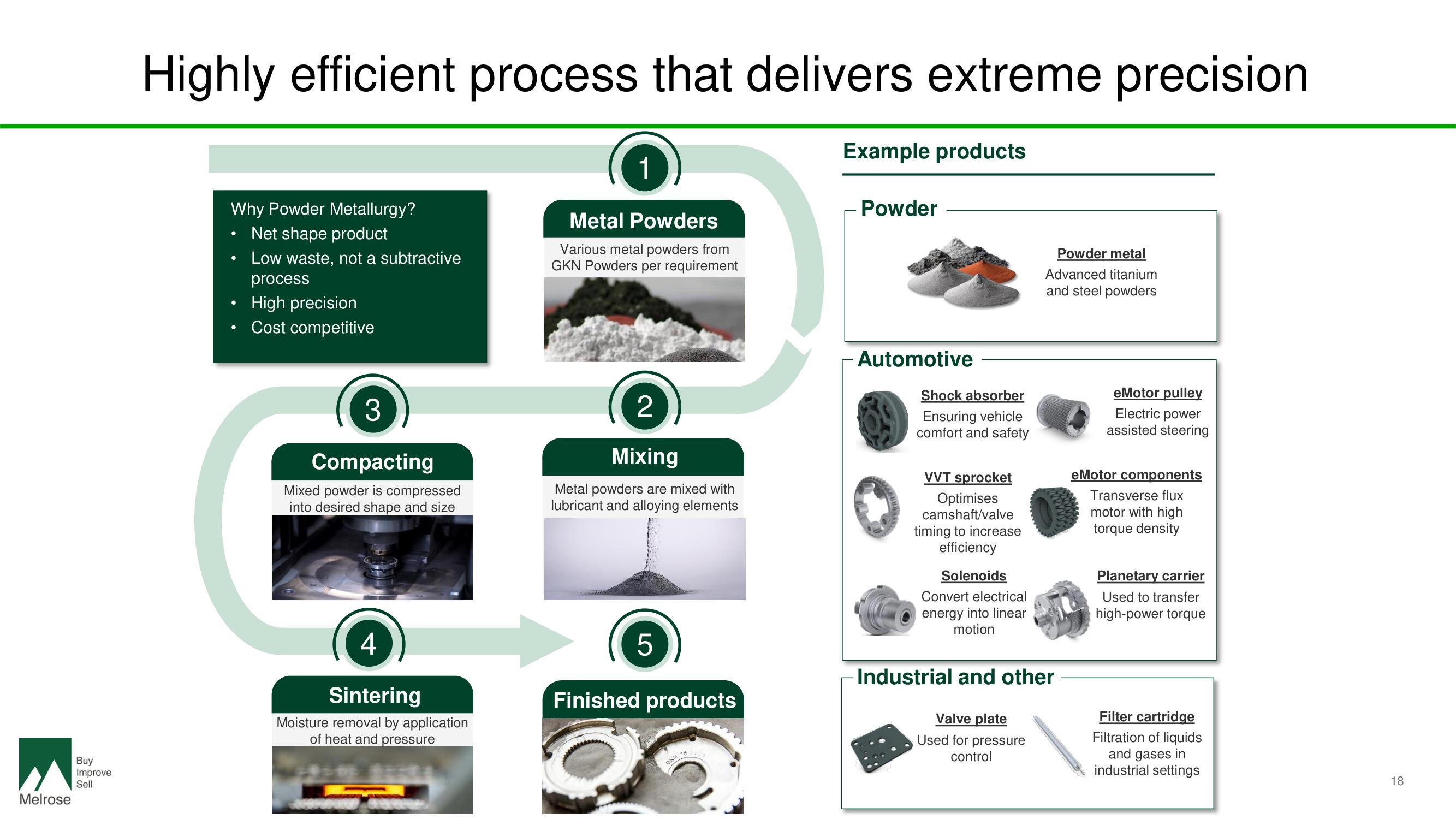

Highly efficient process that delivers extreme precision

Why Powder Metallurgy?

Net shape product

Low waste, not a subtractive

process

High precision

Cost competitive

●

●

●

●

3

Compacting

Mixed powder is compressed

into desired shape and size

4

Sintering

Moisture removal by application

of heat and pressure

1

Metal Powders

Various metal powders from

GKN Powders per requirement

2

Mixing

Metal powders are mixed with

lubricant and alloying elements

5

Finished products

GKM 10

Example products

Powder

Automotive

Shock absorber

Ensuring vehicle

comfort and safety

VVT sprocket

Optimises

camshaft/valve

timing to increase

efficiency

Solenoids

Convert electrical

energy into linear

motion

Powder metal

Advanced titanium

and steel powders

Industrial and other

Valve plate

Used for pressure

control

eMotor pulley

Electric power

assisted steering

eMotor components

Transverse flux

motor with high

torque density

Planetary carrier

Used to transfer

high-power torque

Filter cartridge

Filtration of liquids

and gases in

industrial settings

18View entire presentation