Market Trends, Materials & Manufacturing Processes

go PV

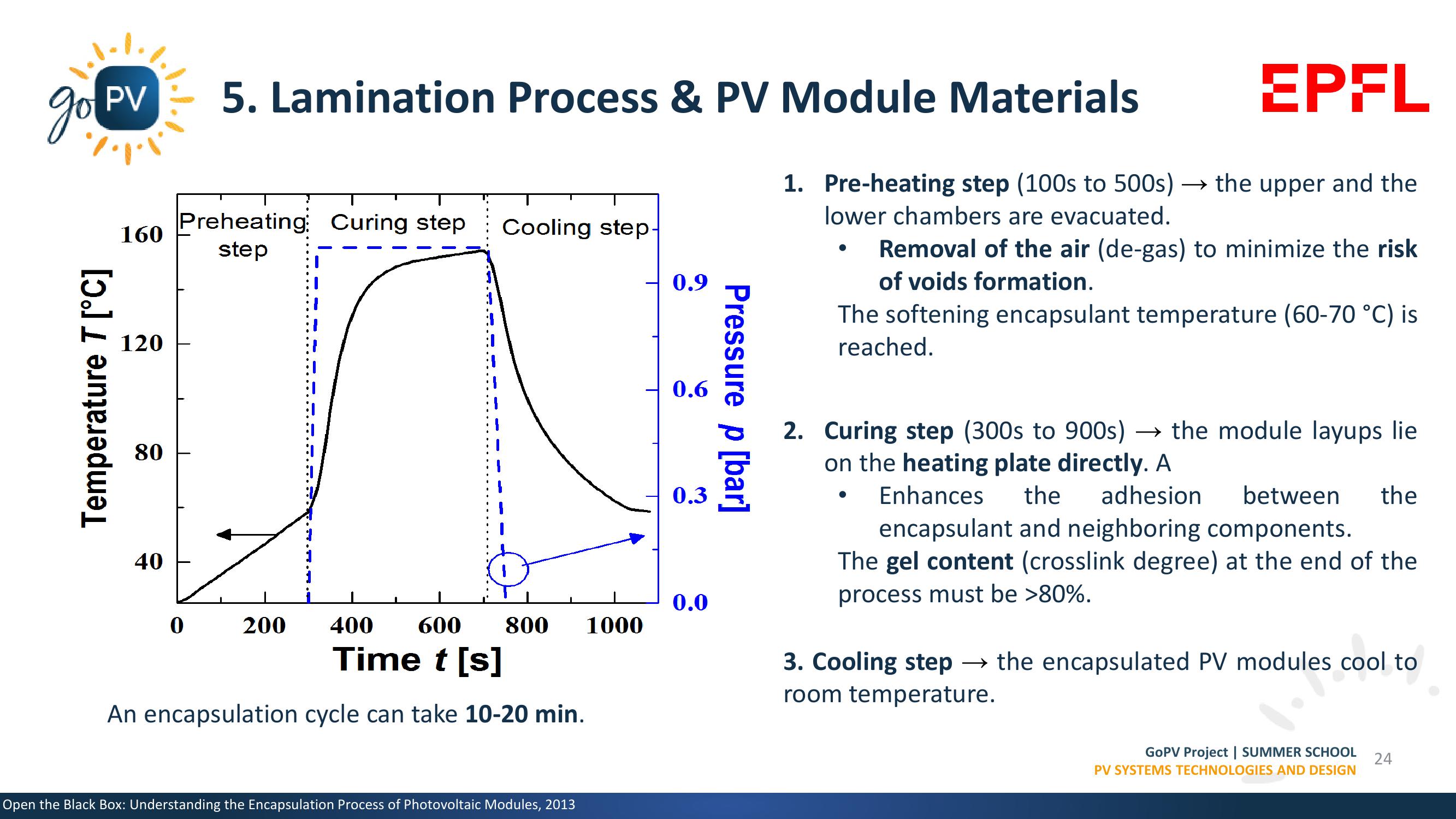

Temperature 7 [°C]

5. Lamination Process & PV Module Materials

step

Preheating: Curing step

160

Cooling step-

0.9

120

80

40

0.6

0.3

0.0

0

200 400 600 800

1000

Time t[s]

An encapsulation cycle can take 10-20 min.

Pressure p [bar]

-

EPFL

1. Pre-heating step (100s to 500s) → the upper and the

lower chambers are evacuated.

Removal of the air (de-gas) to minimize the risk

of voids formation.

The softening encapsulant temperature (60-70 °C) is

reached.

2. Curing step (300s to 900s) → the module layups lie

on the heating plate directly. A

Enhances

the adhesion

between the

encapsulant and neighboring components.

The gel content (crosslink degree) at the end of the

process must be >80%.

→

3. Cooling step the encapsulated PV modules cool to

room temperature.

Open the Black Box: Understanding the Encapsulation Process of Photovoltaic Modules, 2013

GoPV Project | SUMMER SCHOOL 24

PV SYSTEMS TECHNOLOGIES AND DESIGNView entire presentation