Adani Green Energy Limited

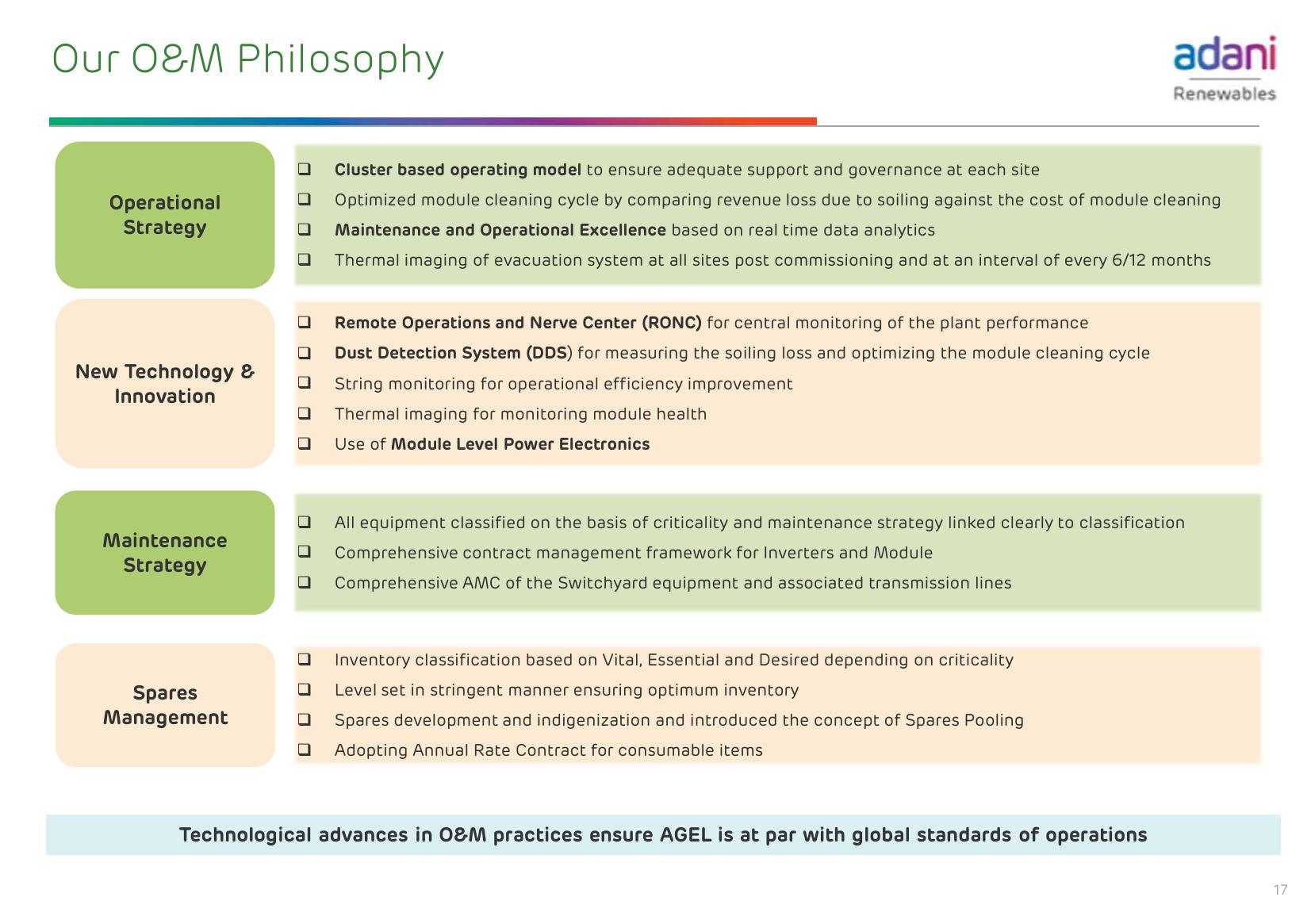

Our O&M Philosophy

adani

Renewables

☐

Cluster based operating model to ensure adequate support and governance at each site

Operational

☐

Strategy

☐

☐

Optimized module cleaning cycle by comparing revenue loss due to soiling against the cost of module cleaning

Maintenance and Operational Excellence based on real time data analytics

Thermal imaging of evacuation system at all sites post commissioning and at an interval of every 6/12 months

☐

Remote Operations and Nerve Center (RONC) for central monitoring of the plant performance

☐

New Technology &

Innovation

ㅁ

Dust Detection System (DDS) for measuring the soiling loss and optimizing the module cleaning cycle

String monitoring for operational efficiency improvement

Thermal imaging for monitoring module health

Use of Module Level Power Electronics

☐

Maintenance

Strategy

☐

All equipment classified on the basis of criticality and maintenance strategy linked clearly to classification

Comprehensive contract management framework for Inverters and Module

☐

Comprehensive AMC of the Switchyard equipment and associated transmission lines

Inventory classification based on Vital, Essential and Desired depending on criticality

Spares

Management

☐

Level set in stringent manner ensuring optimum inventory

☐

Spares development and indigenization and introduced the concept of Spares Pooling

☐ Adopting Annual Rate Contract for consumable items

Technological advances in O&M practices ensure AGEL is at par with global standards of operations

17View entire presentation