MP Materials SPAC Presentation Deck

SUSTAINABLY-SOURCED MATERIALS POWERING THE GREEN REVOLUTION

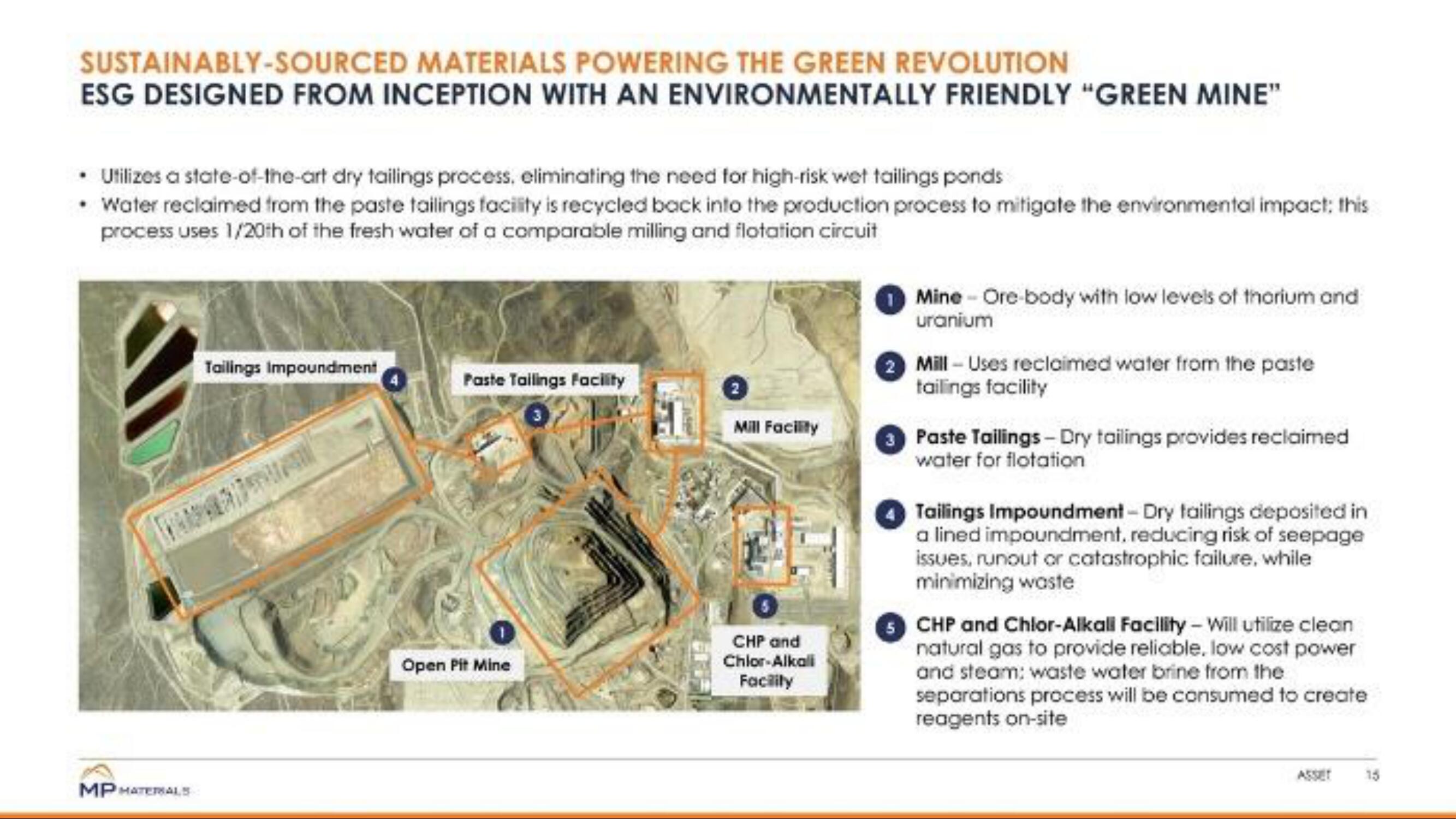

ESG DESIGNED FROM INCEPTION WITH AN ENVIRONMENTALLY FRIENDLY "GREEN MINE"

Utilizes a state-of-the-art dry tailings process, eliminating the need for high-risk wet tailings ponds

• Water reclaimed from the paste tailings facility is recycled back into the production process to mitigate the environmental impact; this

process uses 1/20th of the fresh water of a comparable milling and flotation circuit

MPMATERIALS

Tailings Impoundment

Paste Tailings Facility

Open Pit Mine

Mill Facility

CHP and

Chlor-Alkali

Facility

Mine - Ore-body with low levels of thorium and

uranium

2 Mill - Uses reclaimed water from the paste

tailings facility

3 Paste Tailings - Dry tailings provides reclaimed

water for flotation

Tailings Impoundment-Dry failings deposited in

a lined impoundment, reducing risk of seepage

issues, runout or catastrophic failure, while

minimizing waste

5 CHP and Chlor-Alkali Facility - Will utilize clean

natural gas to provide reliable, low cost power

and steam; waste water brine from the

separations process will be consumed to create

reagents on-siteView entire presentation