Faraday Future SPAC Presentation Deck

4. Flexible Manufacturing Strategy Provides a Clear Path to Production

2021 FARADAY FUTURE

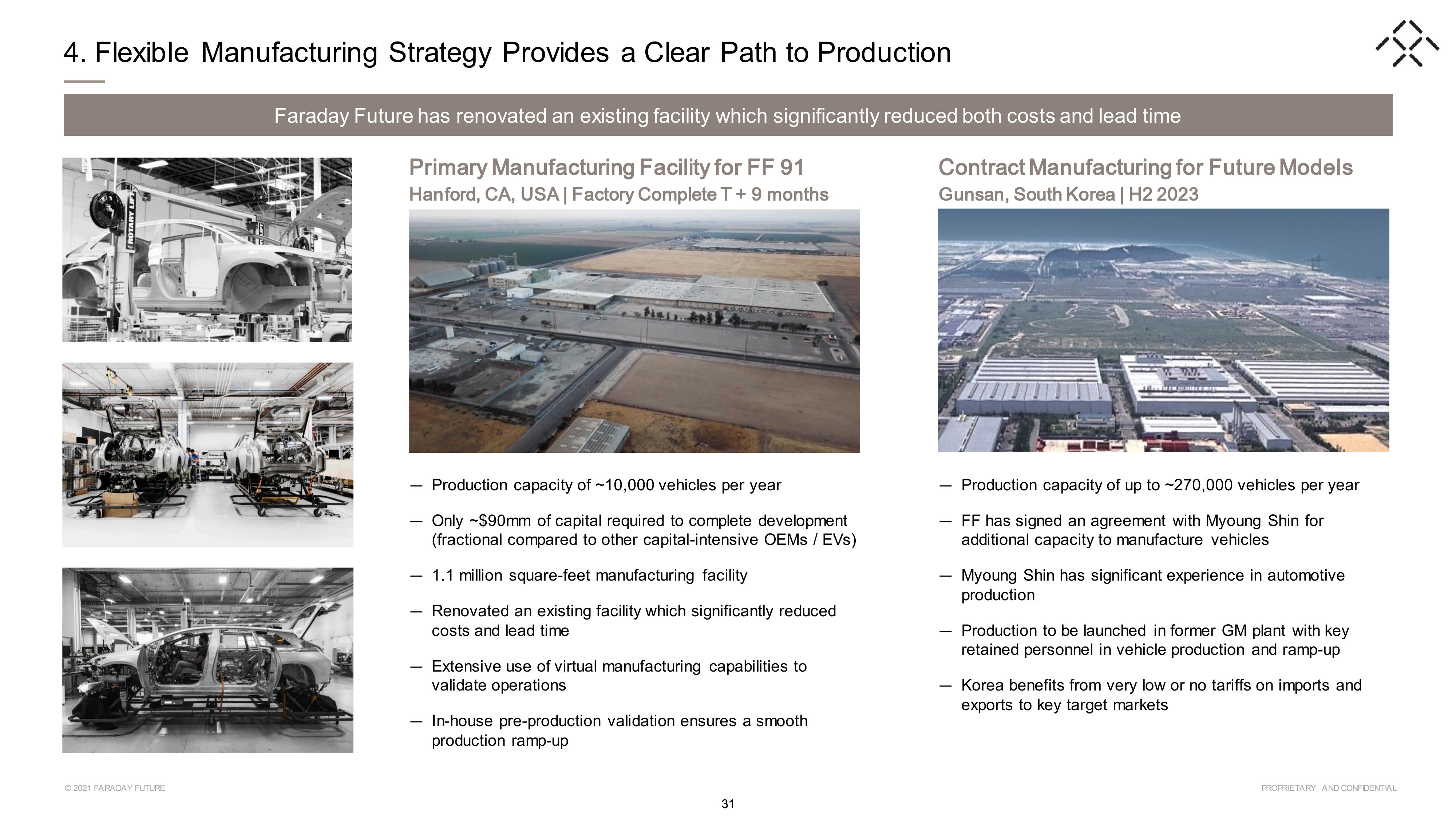

Faraday Future has renovated an existing facility which significantly reduced both costs and lead time

Primary Manufacturing Facility for FF 91

Hanford, CA, USA | Factory Complete T + 9 months

Production capacity of ~10,000 vehicles per year

Only $90mm of capital required to complete development

(fractional compared to other capital-intensive OEMs / EVS)

- 1.1 million square-feet manufacturing facility

Renovated an existing facility which significantly reduced

costs and lead time

Extensive use of virtual manufacturing capabilities to

validate operations

- In-house pre-production validation ensures a smooth

production ramp-up

31

Contract Manufacturing for Future Models

Gunsan, South Korea | H2 2023

ப

Production capacity of up to ~270,000 vehicles per year

FF has signed an agreement with Myoung Shin for

additional capacity to manufacture vehicles

Myoung Shin has significant experience in automotive

production

- Production to be launched in former GM plant with key

retained personnel in vehicle production and ramp-up

- Korea benefits from very low or no tariffs on imports and

exports to key target markets

38

PROPRIETARY AND CONFIDENTIALView entire presentation