Eos Energy Results Presentation Deck

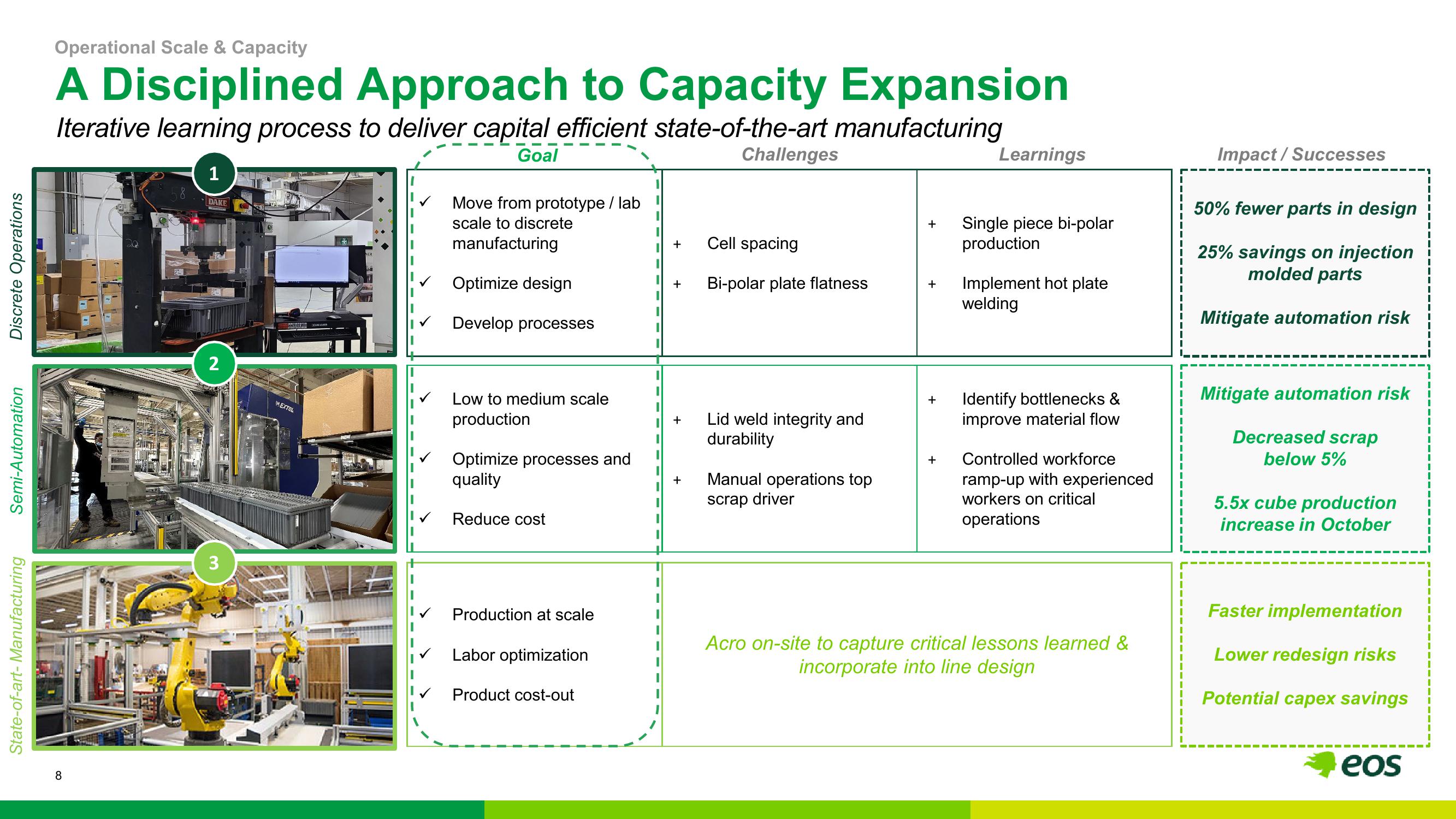

Discrete Operations

Semi-Automation

State-of-art- Manufacturing

Operational Scale & Capacity

A Disciplined Approach to Capacity Expansion

Iterative learning process to deliver capital efficient state-of-the-art manufacturing

Goal

8

1

DAKE

2

3

SOOVRE

EXTOL

DONCLER

B

Move from prototype / lab I

1

scale to discrete

manufacturing

Optimize design

Develop processes

Low to medium scale

production

Optimize processes and

quality

Reduce cost

Production at scale

Labor optimization

Product cost-out

+

+

+

+

Challenges

Cell spacing

Bi-polar plate flatness

Lid weld integrity and

durability

Manual operations top

scrap driver

+ Single piece bi-polar

production

+

Learnings

+

Implement hot plate

welding

Identify bottlenecks &

improve material flow

+ Controlled workforce

ramp-up with experienced

workers on critical

operations

Acro on-site to capture critical lessons learned &

incorporate into line design

Impact/Successes

50% fewer parts in design

25% savings on injection

molded parts

Mitigate automation risk

Mitigate automation risk

Decreased scrap

below 5%

5.5x cube production

increase in October

Faster implementation

Lower redesign risks

Potential capex savings

eosView entire presentation