The Global Solar Photovoltaic Supply Chain and Bottom-UP Cost Model Results

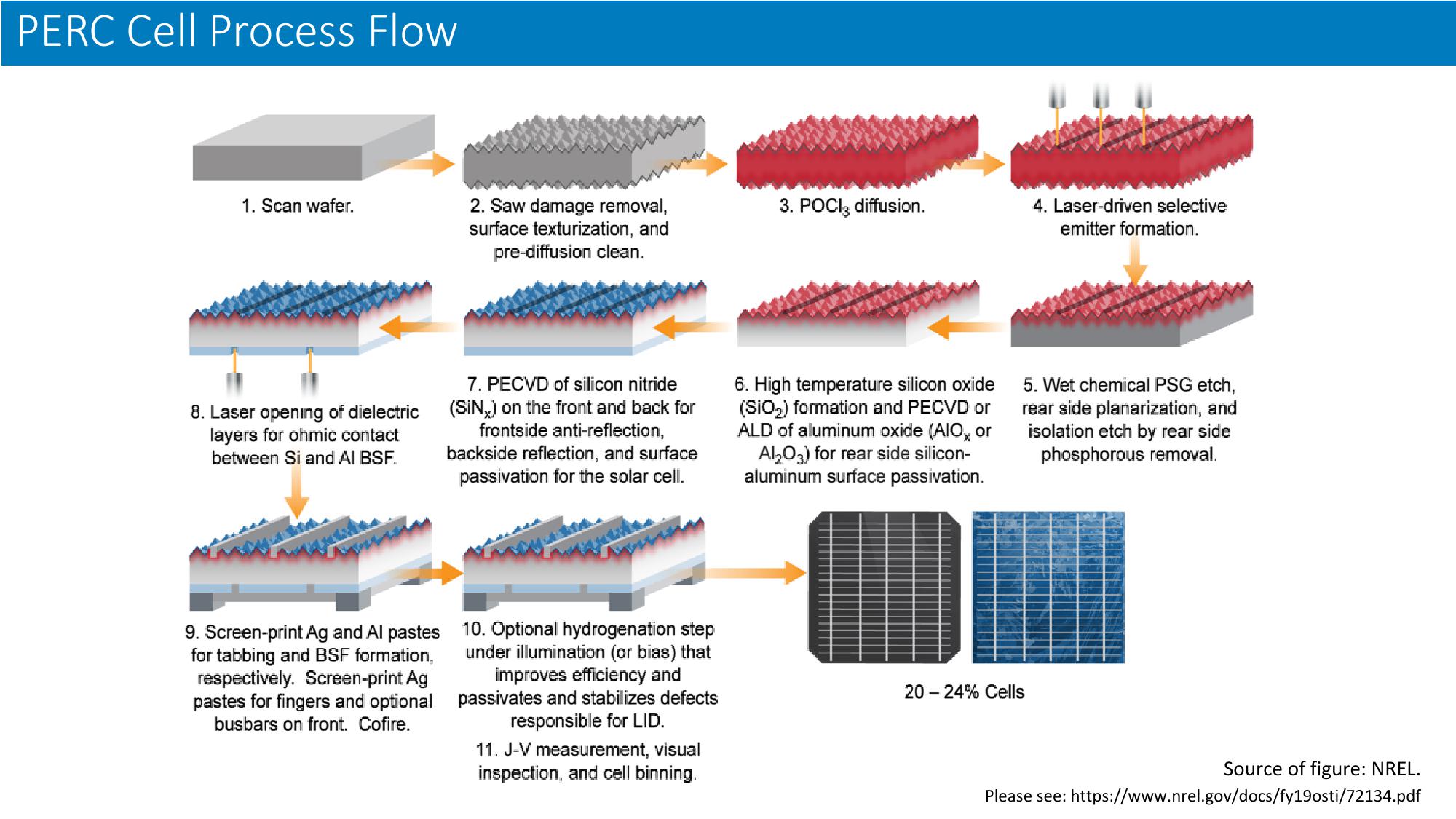

PERC Cell Process Flow

1. Scan wafer.

2. Saw damage removal,

surface texturization, and

pre-diffusion clean.

3. POCI3 diffusion.

4. Laser-driven selective

emitter formation.

8. Laser opening of dielectric

layers for ohmic contact

between Si and AI BSF.

7. PECVD of silicon nitride

(SiNX) on the front and back for

frontside anti-reflection,

backside reflection, and surface

passivation for the solar cell.

6. High temperature silicon oxide

(SiO2) formation and PECVD or

ALD of aluminum oxide (AIO* or

Al2O3) for rear side silicon-

aluminum surface passivation.

5. Wet chemical PSG etch,

rear side planarization, and

isolation etch by rear side

phosphorous removal.

9. Screen-print Ag and Al pastes

for tabbing and BSF formation,

respectively. Screen-print Ag

pastes for fingers and optional

busbars on front. Cofire.

10. Optional hydrogenation step

under illumination (or bias) that

improves efficiency and

passivates and stabilizes defects

responsible for LID.

11. J-V measurement, visual

inspection, and cell binning.

20-24% Cells

Source of figure: NREL.

Please see: https://www.nrel.gov/docs/fy19osti/72134.pdfView entire presentation