Owens&Minor Investor Conference Presentation Deck

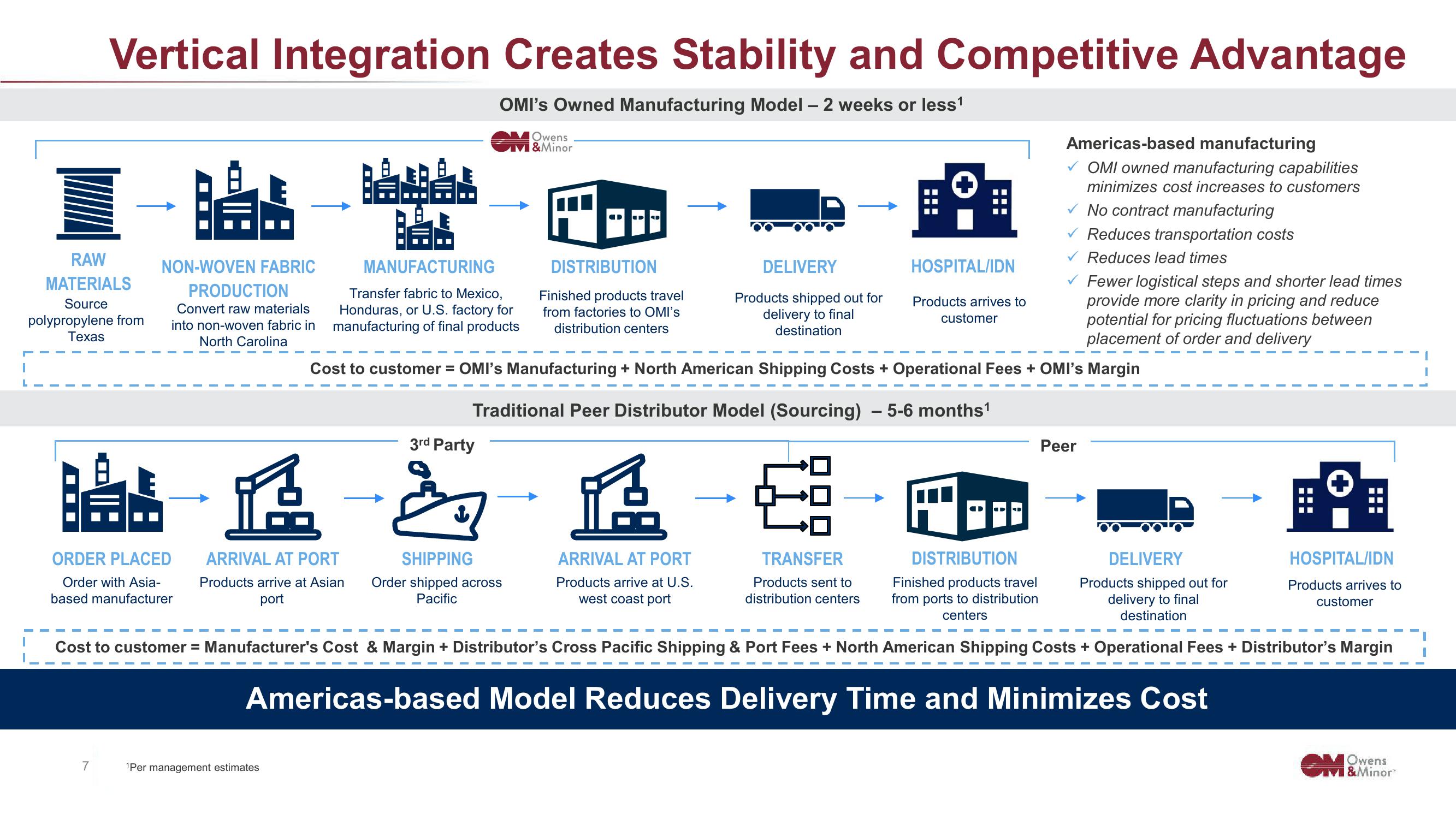

Vertical Integration Creates Stability and Competitive Advantage

OMI's Owned Manufacturing Model - 2 weeks or less¹

RAW

MATERIALS

Source

polypropylene from

Texas

BA

NON-WOVEN FABRIC

PRODUCTION

Convert raw materials

into non-woven fabric in

North Carolina

2.5

A

ORDER PLACED

Order with Asia-

based manufacturer

7

MANUFACTURING

Transfer fabric to Mexico,

Honduras, or U.S. factory for

manufacturing of final products

ARRIVAL AT PORT

Products arrive at Asian

port

¹Per management estimates

3rd Party

al

Owens

SHIPPING

Order shipped across

Pacific

DISTRIBUTION

Finished products travel

from factories to OMI's

distribution centers

DELIVERY

Products shipped out for

delivery to final

destination

1²

ARRIVAL AT PORT

Products arrive at U.S.

west coast port

HOSPITAL/IDN

TRANSFER

Products sent to

distribution centers

Products arrives to

Cost to customer = OMI's Manufacturing + North American Shipping Costs + Operational Fees + OMI's Margin

Traditional Peer Distributor Model (Sourcing) – 5-6 months¹

customer

Americas-based manufacturing

OMI owned manufacturing capabilities

minimizes cost increases to customers

✓ No contract manufacturing

DISTRIBUTION

Finished products travel

from ports to distribution

centers

Reduces transportation costs

Reduces lead times

Peer

Fewer logistical steps and shorter lead times

provide more clarity in pricing and reduce

potential for pricing fluctuations between

placement of order and delivery

Americas-based Model Reduces Delivery Time and Minimizes Cost

+

DELIVERY

Products shipped out for

delivery to final

destination

Cost to customer = Manufacturer's Cost & Margin + Distributor's Cross Pacific Shipping & Port Fees + North American Shipping Costs + Operational Fees + Distributor's Margin

===

HOSPITAL/IDN

Products arrives to

customer

Owens

IMI & MinorView entire presentation