PV Modules: Bifacial technology

go PV

Introduction

Module Bifaciality

Pmpp back

Module Bifaciality =

Pmpp front

tecnalia

Inspiring

Business

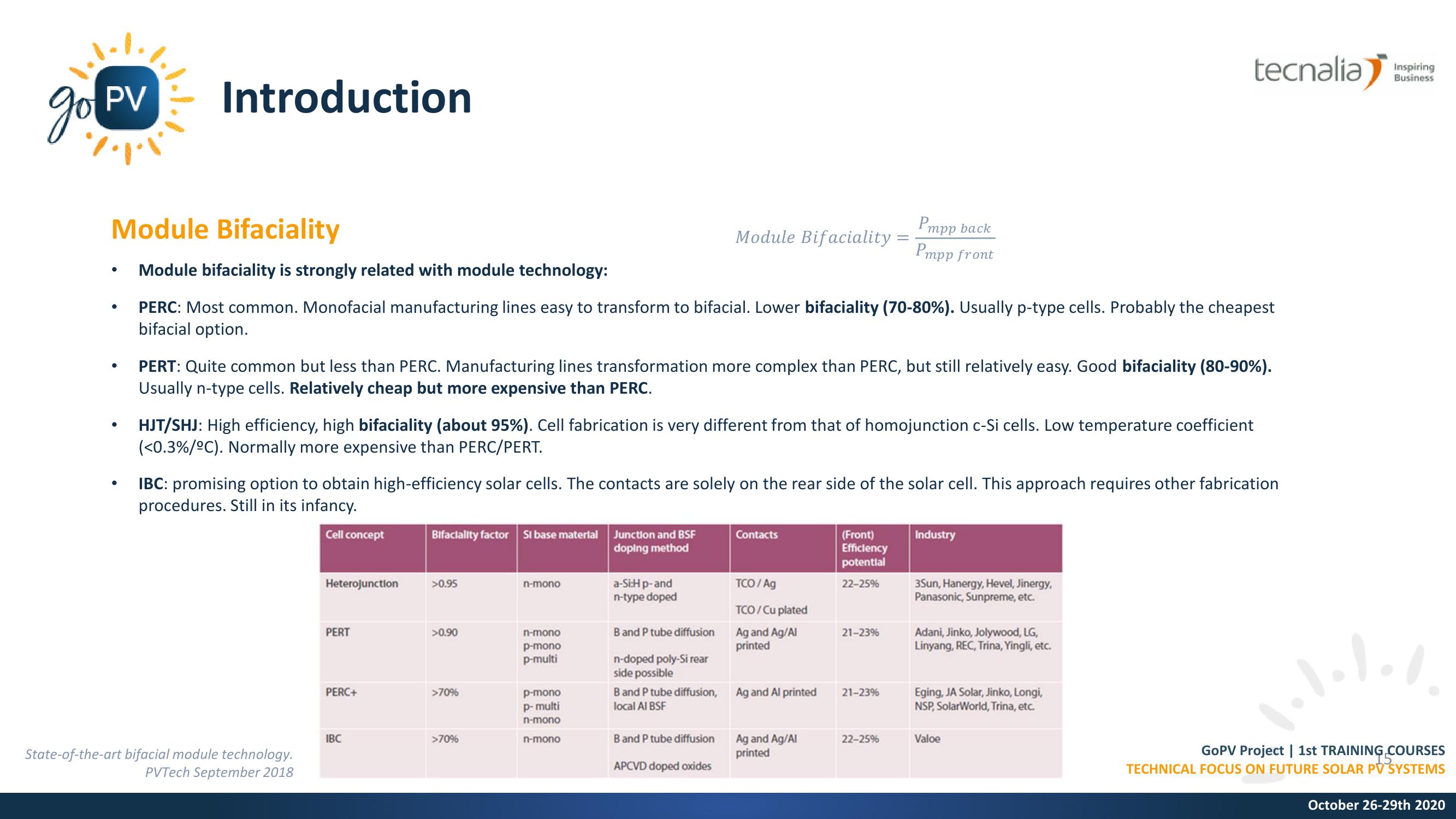

Module bifaciality is strongly related with module technology:

PERC: Most common. Monofacial manufacturing lines easy to transform to bifacial. Lower bifaciality (70-80%). Usually p-type cells. Probably the cheapest

bifacial option.

PERT: Quite common but less than PERC. Manufacturing lines transformation more complex than PERC, but still relatively easy. Good bifaciality (80-90%).

Usually n-type cells. Relatively cheap but more expensive than PERC.

HJT/SHJ: High efficiency, high bifaciality (about 95%). Cell fabrication is very different from that of homojunction c-Si cells. Low temperature coefficient

(<0.3% /ºC). Normally more expensive than PERC/PERT.

IBC: promising option to obtain high-efficiency solar cells. The contacts are solely on the rear side of the solar cell. This approach requires other fabrication

procedures. Still in its infancy.

Cell concept

Bifaciality factor Si base material Junction and BSF

doping method

Contacts

Heterojunction

>0.95

n-mono

a-Si:H p-and

n-type doped

TCO/Ag

(Front)

Efficiency

potential

22-25%

Industry

TCO/Cu plated

PERT

>0.90

n-mono

p-mono

B and P tube diffusion

Ag and Ag/Al

printed

21-23%

3Sun, Hanergy, Hevel, Jinergy,

Panasonic, Sunpreme, etc.

Adani, Jinko, Jolywood, LG,

Linyang, REC, Trina, Yingli, etc.

p-multi

n-doped poly-Si rear

side possible

PERC+

>70%

p-mono

p-multi

B and P tube diffusion, Ag and Al printed

local AI BSF

21-23%

Eging, JA Solar, Jinko, Longi,

NSP, SolarWorld, Trina, etc.

n-mono

IBC

>70%

n-mono

B and P tube diffusion

Ag and Ag/Al

22-25%

Valoe

State-of-the-art bifacial module technology.

printed

PVTech September 2018

APCVD doped oxides

GoPV Project | 1st TRAINING COURSES

TECHNICAL FOCUS ON FUTURE SOLAR PV SYSTEMS

October 26-29th 2020View entire presentation