Solid Power SPAC Presentation Deck

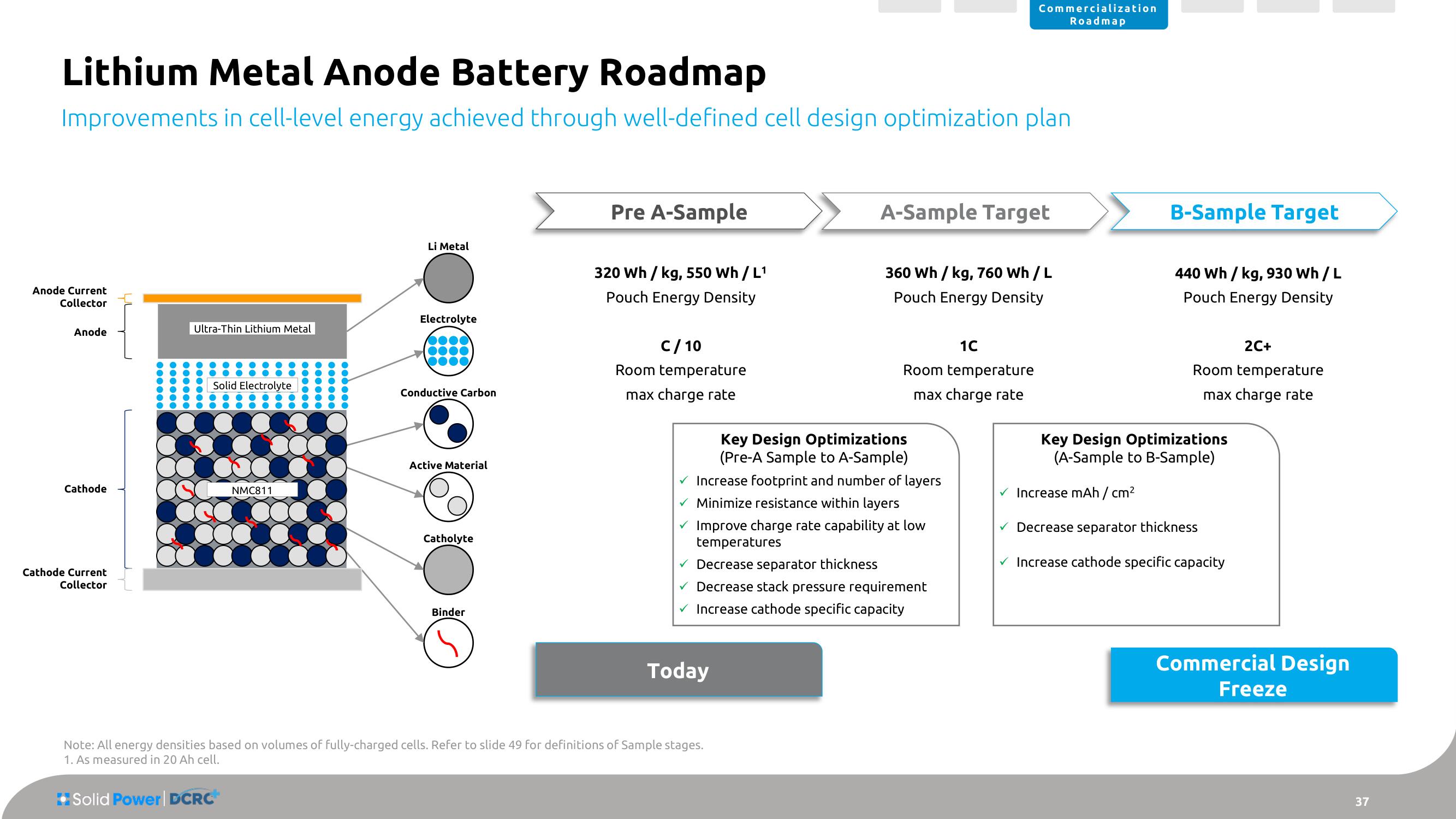

Lithium Metal Anode Battery Roadmap

Improvements in cell-level energy achieved through well-defined cell design optimization plan

Anode Current

Collector

Anode

Cathode

Cathode Current

Collector

Ultra-Thin Lithium Metal

Solid Electrolyte

NMC811

Li Metal

Electrolyte

Conductive Carbon

Active Material

Catholyte

Binder

Pre A-Sample

320 Wh / kg, 550 Wh / L¹

Pouch Energy Density

C/10

Room temperature

max charge rate

Today

A-Sample Target

Key Design Optimizations

(Pre-A Sample to A-Sample)

Increase footprint and number of layers

Minimize resistance within layers

Improve charge rate capability at low

temperatures

Note: All energy densities based on volumes of fully-charged cells. Refer to slide 49 for definitions of Sample stages.

1. As measured in 20 Ah cell.

Solid Power | DCRC

Commercialization

Roadmap

360 Wh / kg, 760 Wh / L

Pouch Energy Density

1C

Room temperature

max charge rate

Decrease separator thickness

Decrease stack pressure requirement

✓ Increase cathode specific capacity

B-Sample Target

440 Wh / kg, 930 Wh / L

Pouch Energy Density

Room temperature

max charge rate

Key Design Optimizations

(A-Sample to B-Sample)

2C+

Increase mAh /cm²

✓ Decrease separator thickness

✓ Increase cathode specific capacity

Commercial Design

Freeze

37View entire presentation