Solid Power SPAC Presentation Deck

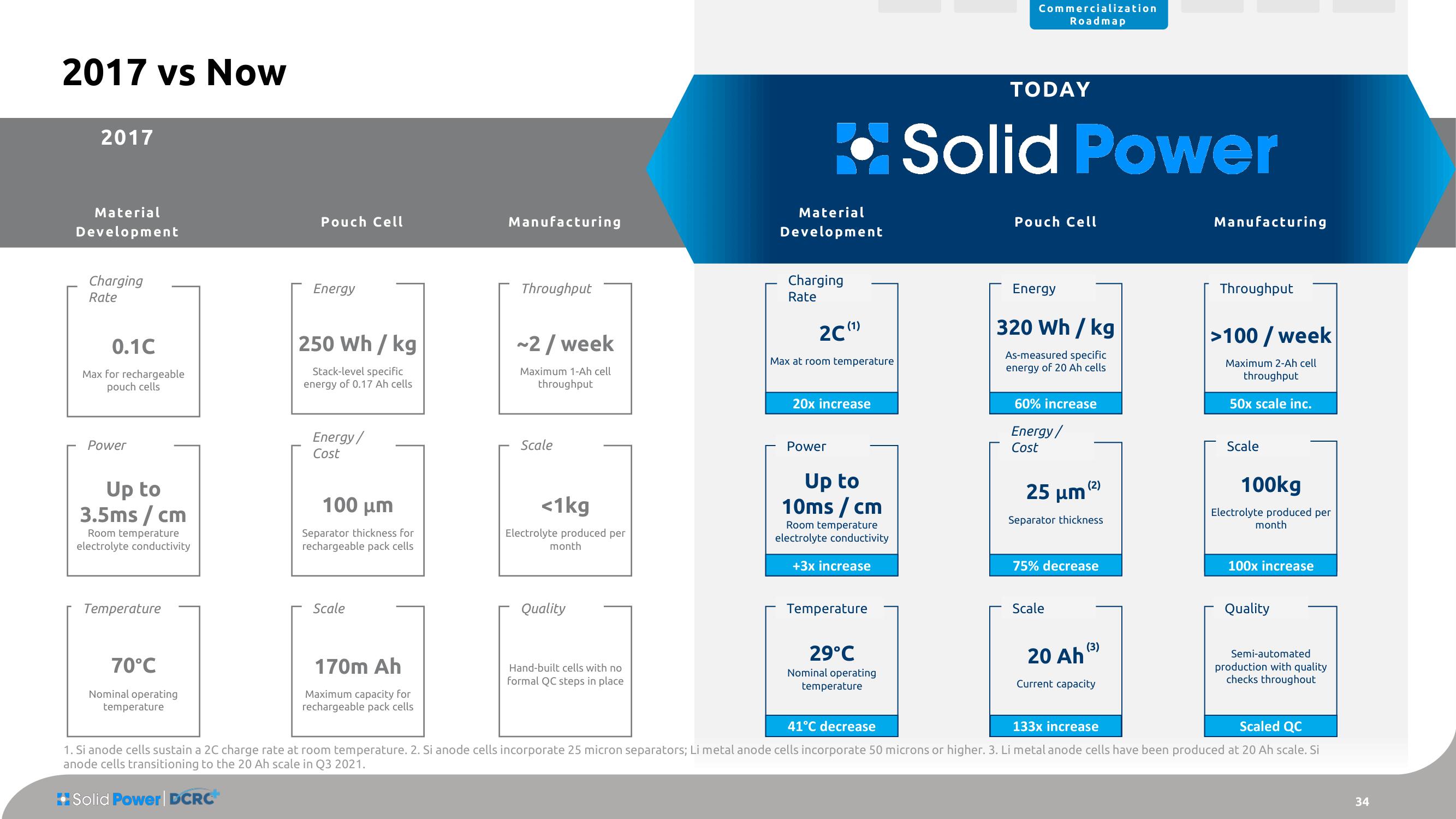

2017 vs Now

2017

Material

Development

Charging

Rate

0.1C

Max for rechargeable

pouch cells

Power

Up to

3.5ms/ cm

Room temperature

electrolyte conductivity

Temperature

70°C

Nominal operating

temperature

Pouch Cell

Energy

250 Wh / kg

Stack-level specific

energy of 0.17 Ah cells

Energy /

Cost

100 μm

Separator thickness for

rechargeable pack cells

Scale

170m Ah

Maximum capacity for

rechargeable pack cells

Manufacturing

Throughput

~2/week

Maximum 1-Ah cell

throughput

Scale

<1kg

Electrolyte produced per

month

Quality

Hand-built cells with no

formal QC steps in place

Material

Development

Charging

Rate

2C (¹)

Max at room temperature

20x increase

Power

Up to

10ms / cm

Room temperature

electrolyte conductivity

+3x increase

Temperature

29°C

Nominal operating

temperature

Commercialization

Roadmap

TODAY

Solid Power

Pouch Cell

Energy

320 Wh / kg

As-measured specific

energy of 20 Ah cells

60% increase

Energy /

Cost

(2)

25 μm

Separator thickness

75% decrease

Scale

(3)

20 Ah

Current capacity

Manufacturing

Throughput

>100 / week

Maximum 2-Ah cell

throughput

50x scale inc.

Scale

100kg

Electrolyte produced per

month

100x increase

Quality

Semi-automated

production with quality

checks throughout

41°C decrease

133x increase

Scaled QC

1. Si anode cells sustain a 2C charge rate at room temperature. 2. Si anode cells incorporate 25 micron separators; Li metal anode cells incorporate 50 microns or higher. 3. Li metal anode cells have been produced at 20 Ah scale. Si

anode cells transitioning to the 20 Ah scale in Q3 2021.

Solid Power DCRC

34View entire presentation