Solid Power SPAC Presentation Deck

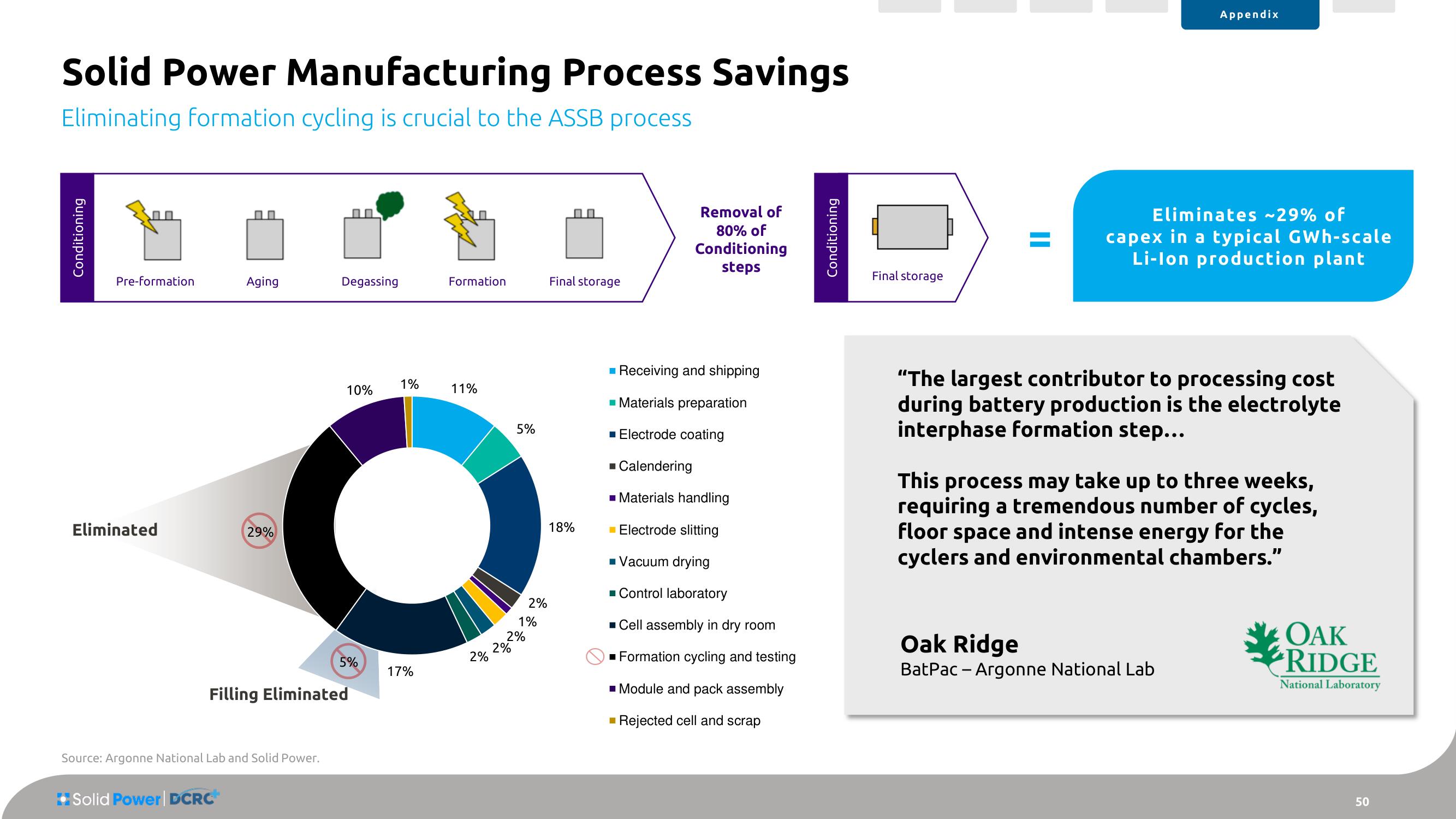

Solid Power Manufacturing Process Savings

Eliminating formation cycling is crucial to the ASSB process

Conditioning

Pre-formation

Eliminated

Aging

29%

Solid Power | DCRC

Source: Argonne National Lab and Solid Power.

Degassing

10%

Filling Eliminated

5%

1%

17%

Formation

11%

2%

5%

2%

2%

2%

1%

Final storage

18%

Removal of

80% of

Conditioning

steps

■ Receiving and shipping

■ Materials preparation

■ Electrode coating

■Calendering

■ Materials handling

■ Electrode slitting

■ Vacuum drying

■ Control laboratory

■ Cell assembly in dry room

■ Formation cycling and testing

▪ Module and pack assembly

Rejected cell and scrap

Conditioning

Final storage

Appendix

Eliminates ~29% of

capex in a typical GWh-scale

Li-Ion production plant

"The largest contributor to processing cost

during battery production is the electrolyte

interphase formation step...

This process may take up to three weeks,

requiring a tremendous number of cycles,

floor space and intense energy for the

cyclers and environmental chambers."

Oak Ridge

BatPac - Argonne National Lab

ОАК

RIDGE

National Laboratory

50View entire presentation