Baran Group Meeting

Terry Lou

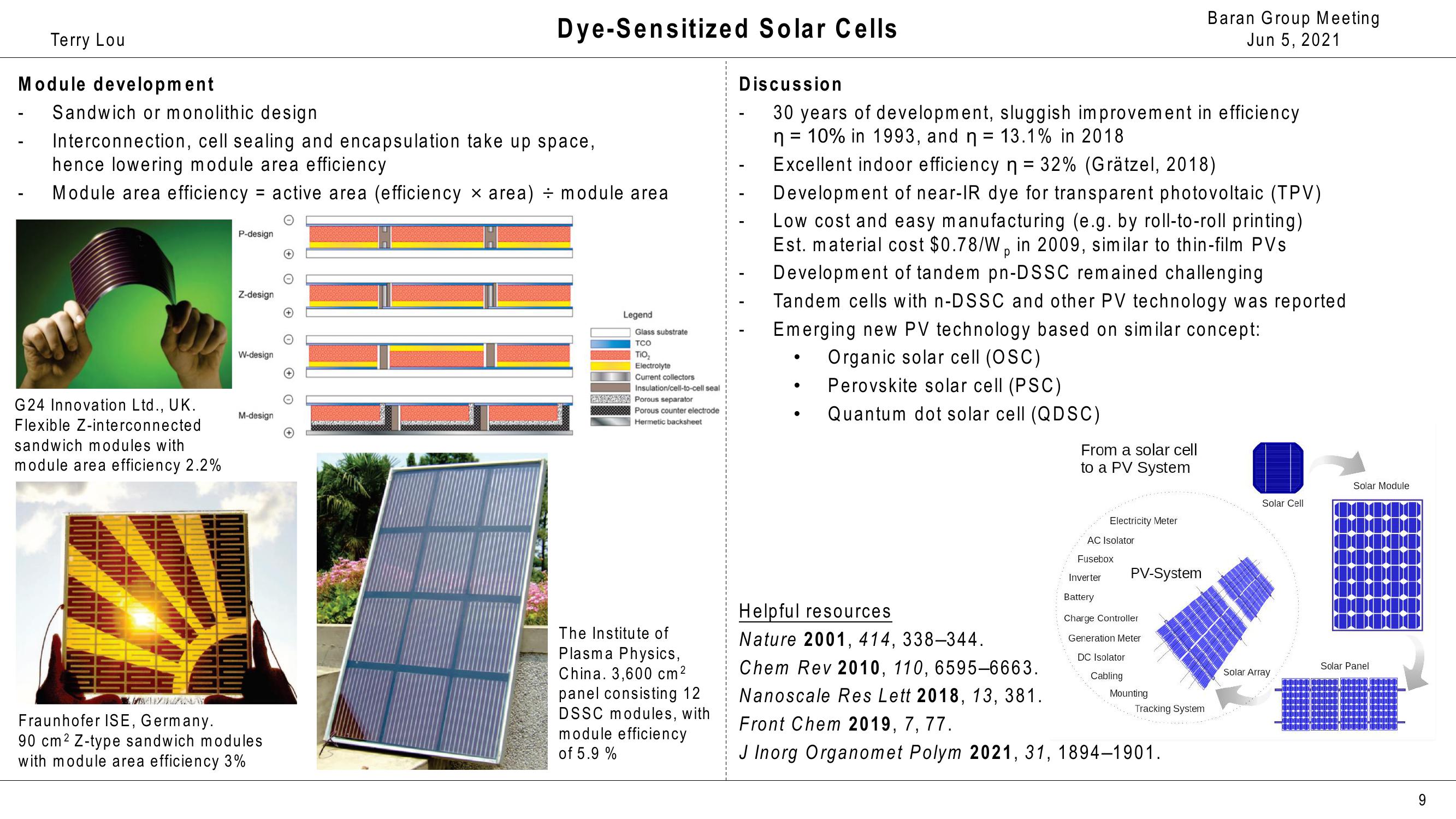

Module development

-

-

-

Sandwich or monolithic design

Dye-Sensitized Solar Cells

Interconnection, cell sealing and encapsulation take up space,

hence lowering module area efficiency

Module area efficiency = active area (efficiency × area) ÷ module area

G24 Innovation Ltd., UK.

Flexible Z-interconnected

sandwich modules with

module area efficiency 2.2%

P-design

Z-design

W-design

M-design

+ O

+ 0

+

Legend

Glass substrate

TCO

ΤΙΟΣ

Electrolyte

Current collectors

Insulation/cell-to-cell seal

Porous separator

Porous counter electrode

Hermetic backsheet

Discussion

Baran Group Meeting

Jun 5, 2021

30 years of development, sluggish improvement in efficiency

n = 10% in 1993, and n = 13.1% in 2018

Excellent indoor efficiency n = 32% (Grätzel, 2018)

Development of near-IR dye for transparent photovoltaic (TPV)

Low cost and easy manufacturing (e.g. by roll-to-roll printing)

Est. material cost $0.78/Wp in 2009, similar to thin-film PVs

Development of tandem pn-DSSC remained challenging

Tandem cells with n-DSSC and other PV technology was reported

Emerging new PV technology based on similar concept:

•

Organic solar cell (OSC)

.

Perovskite solar cell (PSC)

•

Quantum dot solar cell (QDSC)

From a solar cell

to a PV System

MAY

Fraunhofer ISE, Germany.

90 cm² Z-type sandwich modules

with module area efficiency 3%

The Institute of

Plasma Physics,

China. 3,600 cm²

panel consisting 12

DSSC modules, with

module efficiency

of 5.9 %

Helpful resources

Nature 2001, 414, 338–344.

Chem Rev 2010, 110, 6595-6663.

Nanoscale Res Lett 2018, 13, 381.

Front Chem 2019, 7, 77.

Electricity Meter

AC Isolator

Fusebox

Inverter

Battery

PV-System

Charge Controller

Generation Meter

DC Isolator

Cabling

Mounting

Tracking System

J Inorg Organomet Polym 2021, 31, 1894-1901.

Solar Module

Solar Cell

Solar Panel

Solar Array

6View entire presentation