Nikola SPAC Presentation Deck

H₂ STATION UNIT ECONOMICS

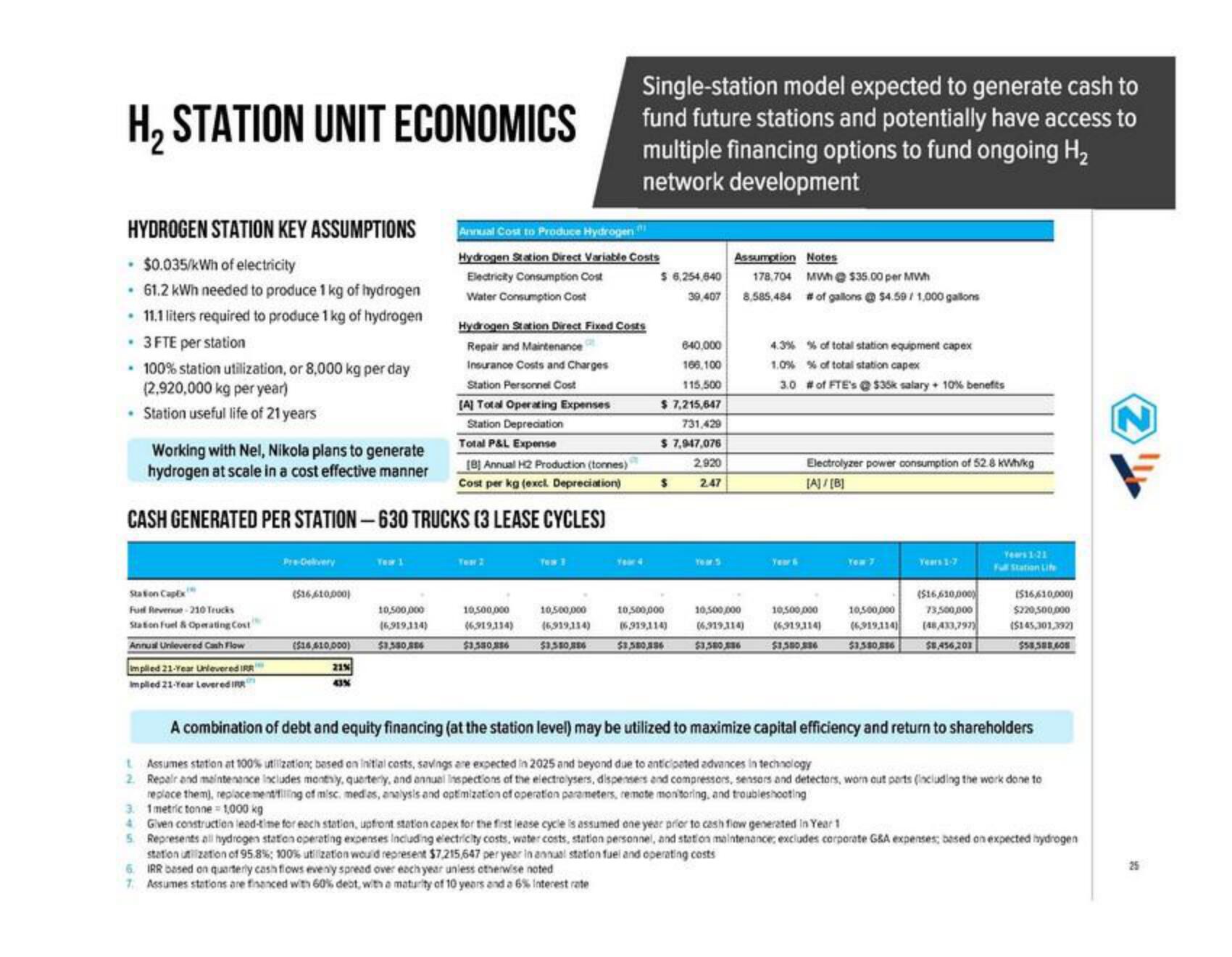

HYDROGEN STATION KEY ASSUMPTIONS

$0.035/kWh of electricity

• 61.2 kWh needed to produce 1 kg of hydrogen

• 11.1 liters required to produce 1 kg of hydrogen

3FTE per station

. 100% station utilization, or 8,000 kg per day

(2,920,000 kg per year)

• Station useful life of 21 years

.

Working with Nel, Nikola plans to generate

hydrogen at scale in a cost effective manner

Hydrogen Station Direct Fixed Costs

Repair and Maintenance

Insurance Costs and Charges

Station Personnel Cost

[A] Total Operating Expenses

Station Depreciation

Total P&L Expense

[8] Annual H2 Production (tonnes)

Cost per kg (excl. Depreciation)

CASH GENERATED PER STATION-630 TRUCKS (3 LEASE CYCLES)

Station CapEx

Full Revenue -210 Trucks

Station Fuel & Operating Cost

Annual Unlevered Cash Flow

implied 21-Year Unlevered IRR

implied 21-Year Lovered IRR

Pre-Delivery

($16,610,000)

($16,410,000)

21%

10,500,000

(6,919,114)

$1,550,886

Annual Cost to Produce Hydrogen

Hydrogen Station Direct Variable Costs

Electricity Consumption Cost

Water Consumption Cost

10,500,000

(6,919,114)

$1,550,556

Single-station model expected to generate cash to

fund future stations and potentially have access to

multiple financing options to fund ongoing H₂

network development

Yew 3

10,500,000

(6,919,114)

$1,550,886

Year 4

$ 6,254,640

39,407

640,000

166,100

115,500

$ 7,215,647

731,429

$ 7,947,076

$

10,500,000

(6919,114)

$3,580,356

2,920

2.47

Year 5

Assumption Notes

178,704 MWh @ $35.00 per MWh

8,585,484 # of gallons@ $4.59/1,000 gallons

10,500,000

(6,919,114)

$3,580,36

4.3% % of total station equipment capex

1.0% % of total station capex

3.0 # of FTE's @ $35k salary + 10% benefits

Years

Electrolyzer power consumption of 52.8 kWh/kg

[A]/[B]

10,500,000

(6,919,114)

$1,500,986

You 7

Years 1-7

($16,610,000)

10,500,000

73,500,000

(6,919,114) (48,433,797)

$1,550,556 $8,456,201

Years 1-21

Full Station Life

($16,610,000)

$220,500,000

($145,301,392)

$58,588,608

A combination of debt and equity financing (at the station level) may be utilized to maximize capital efficiency and return to shareholders

t Assumes station at 100% utilization, based on initial costs, savings are expected in 2025 and beyond due to anticipated advances in technology

2.

Repair and maintenance includes monthly, quarterly, and annual Inspections of the electrolysers, dispensers and compressors, sensors and detectors, worn out parts (including the work done to

replace them), replacementfiling of misc. medas, analysis and optimization of operation parameters, remote monitoring, and troubleshooting

3. 1metric tonne = 1,000 kg

4 Given construction lead-time for each station, upfront station capex for the first lease cycle is assumed one year prior to cash flow generated in Year 1

5. Represents all hydrogen station operating expenses including electricity costs, water costs, station personnel, and station maintenance; excludes corporate G&A expenses; based on expected hydrogen

station utilization of 95.8%; 100% utilization would represent $7,215,647 per year in annual station fuel and operating costs

6. IRR based on quarterly cash flows evenly spread over each year unless otherwise noted

7. Assumes stations are financed with 60% debt, with a maturity of 10 years and a 6% Interest rate

25View entire presentation