Evercore Investment Banking Pitch Book

Soda Ash Market Background

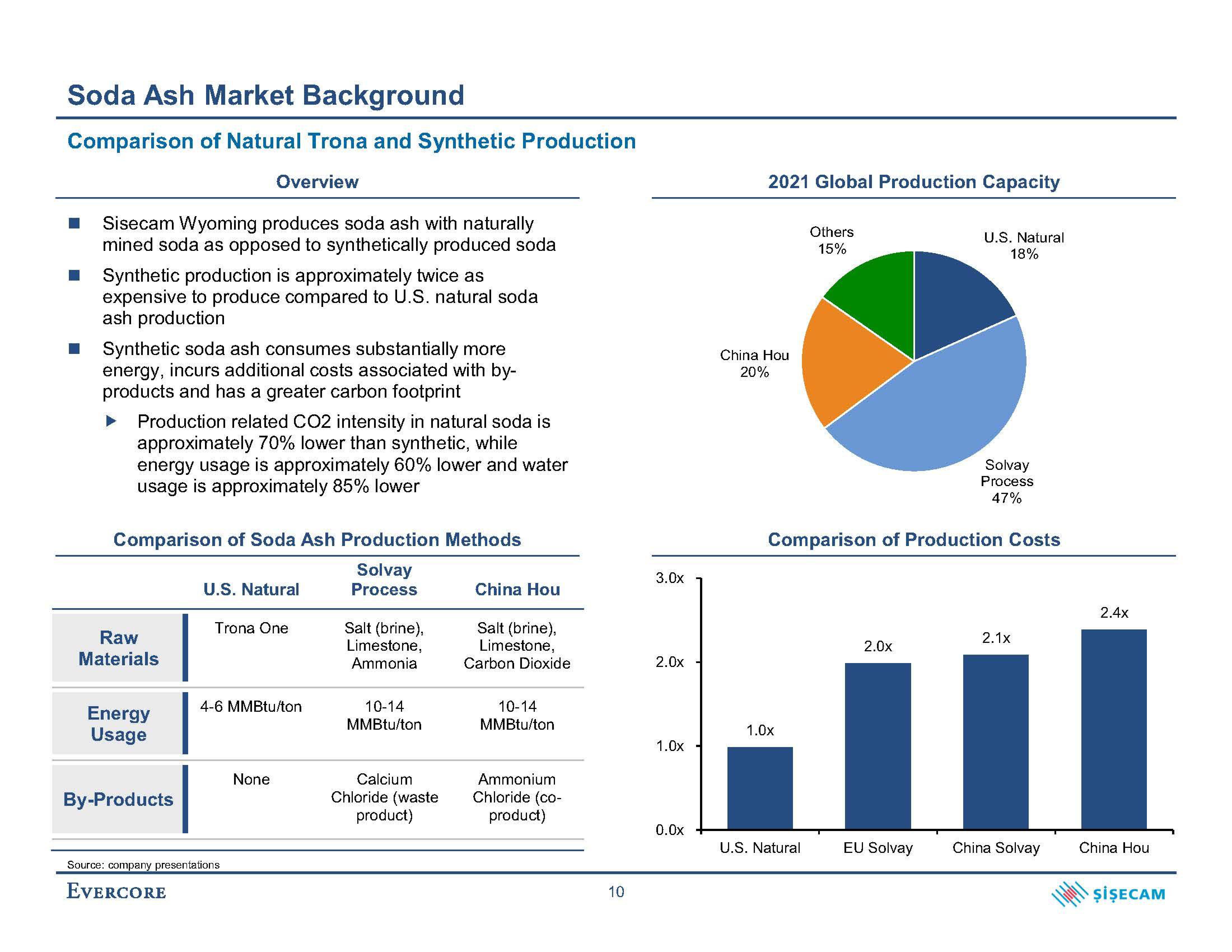

Comparison of Natural Trona and Synthetic Production

Overview

Sisecam Wyoming produces soda ash with naturally

mined soda as opposed to synthetically produced soda

Synthetic production is approximately twice as

expensive to produce compared to U.S. natural soda

ash production

■ Synthetic soda ash consumes substantially more

energy, incurs additional costs associated with by-

products and has a greater carbon footprint

Production related CO2 intensity in natural soda is

approximately 70% lower than synthetic, while

energy usage is approximately 60% lower and water

usage is approximately 85% lower

Comparison of Soda Ash Production Methods

Solvay

Process

Raw

Materials

Energy

Usage

By-Products

U.S. Natural

Trona One

4-6 MMBtu/ton

Source: company presentations

EVERCORE

None

Salt (brine),

Limestone,

Ammonia

10-14

MMBtu/ton

Calcium

Chloride (waste

product)

China Hou

Salt (brine),

Limestone,

Carbon Dioxide

10-14

MMBtu/ton

Ammonium

Chloride (co-

product)

10

3.0x

2.0x

1.0x

0.0x

2021 Global Production Capacity

China Hou

20%

1.0x

Others

15%

Solvay

Process

47%

Comparison of Production Costs

U.S. Natural

2.0x

U.S. Natural

18%

EU Solvay

2.1x

China Solvay

2.4x

China Hou

ŞİŞECAMView entire presentation