Capacity, Applications, and Outlook

N-Type Modules Accelerate in Deployment and March Towards 700W

TRENDFORCE

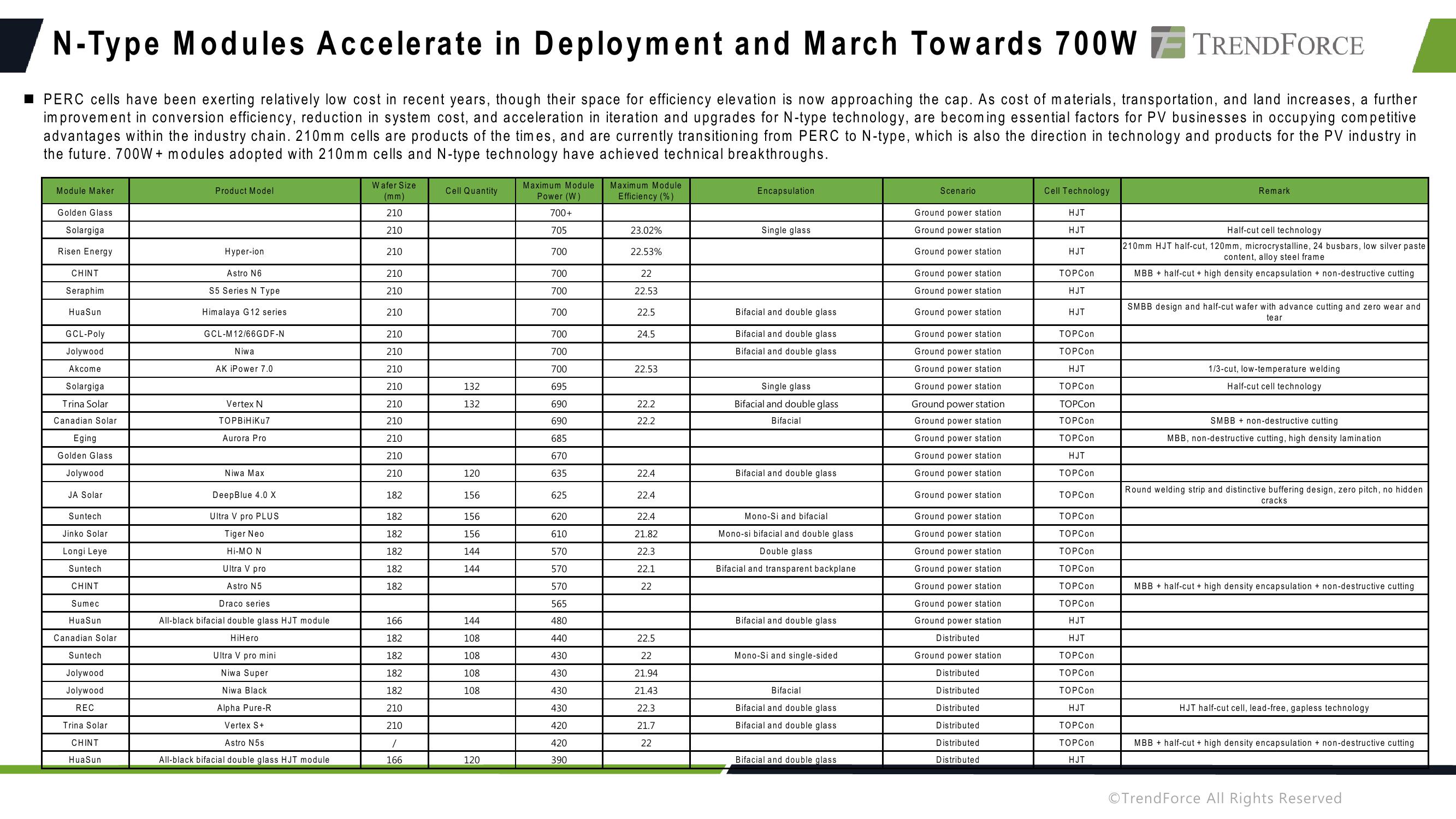

■ PERC cells have been exerting relatively low cost in recent years, though their space for efficiency elevation is now approaching the cap. As cost of materials, transportation, and land increases, a further

improvement in conversion efficiency, reduction in system cost, and acceleration in iteration and upgrades for N-type technology, are becoming essential factors for PV businesses in occupying competitive

advantages within the industry chain. 210mm cells are products of the times, and are currently transitioning from PERC to N-type, which is also the direction in technology and products for the PV industry in

the future. 700W + modules adopted with 210mm cells and N-type technology have achieved technical breakthroughs.

Module Maker

Product Model

Wafer Size

(mm)

Cell Quantity

Maximum Module Maximum Module

Power (W)

Encapsulation

Scenario

Cell Technology

Remark

Efficiency (%)

Golden Glass

Solargigal

Risen Energy

CHINT

Seraphim

210

700+

210

705

23.02%

Single glass

Hyper-ion

Astro N6

210

700

22.53%

Ground power station

Ground power station

Ground power station

HJT

HJT

Half-cut cell technology

HJT

210

700

22

S5 Series N Type

210

HuaSun

Himalaya G12 series

210

GCL-Poly

GCL-M12/66GDF-N

210

Jolywood

Niwa

210

Akcome

AK iPower 7.0

210

Solargiga

210

132

Trina Solar

Vertex N

210

132

Canadian Solar

TOPBiHiKu7

210

Eging

Aurora Pro

210

Golden Glass

210

Jolywood

JA Solar

Niwa Max

210

120

DeepBlue 4.0 X

182

156

Suntech

Ultra V pro PLUS

182

156

Jinko Solar

Tiger Neo

182

156

Longi Leye

Hi-MO N

182

144

Suntech

Ultra V pro

182

144

CHINT

Jolywood

REC

Niwa Black

Alpha Pure-R

Trina Solar

Vertex S+

Astro N5

Sumec

Draco series

HuaSun

All-black bifacial double glass HJT module.

166

144

Canadian Solar

HiHero

182

108

Suntech

Ultra V pro mini

182

108

Jolywood

Niwa Super

182

108

182

108

210

210

182

CHINT

Astro N5s

HuaSun

All-black bifacial double glass HJT module

166

120

88888888388 888RRR9898888888

22.53

Ground power station

Ground power station

TOP Con

210mm HJT half-cut, 120mm, microcrystalline, 24 busbars, low silver paste

content, alloy steel frame

MBB + half-cut + high density encapsulation + non-destructive cutting

HJT

22.5

Bifacial and double glass

24.5

Bifacial and double glass

Bifacial and double glass

22.53

22.2

Single glass

Bifacial and double glass

22.2

Bifacial

22.4

Bifacial and double glass.

22.4

Ground power station

Ground power station

Ground power station

Ground power station

Ground power station

Ground power station

Ground power station

Ground power station

Ground power station

Ground power station

Ground power station

HJT

SMBB design and half-cut wafer with advance cutting and zero wear and

tear

TOPCon

TOP Con

HJT

TOP Con

TOPCon

1/3-cut, low-temperature welding

Half-cut cell technology

TOP Con

TOPCon

HJT

SMBB non-destructive cutting

MBB, non-destructive cutting, high density lamination

TOP Con

Round welding strip and distinctive buffering design, zero pitch, no hidden

TOPCon

cracks

22.4

21.82

22.3

22.1

Mono-Si and bifacial

Mono-si bifacial and double glass

Double glass

Bifacial and transparent backplane

Ground power station

TOP Con

Ground power station

TOPCon

Ground power station

TOPCon

Ground power station

TOPCon

22

Ground power station

Bifacial and double glass

Ground power station

Ground power station

22.5

22

21.94

Distributed

TOPCon

TOPCon

HJT

HJT

MBB + half-cut + high density encapsulation + non-destructive cutting

Mono-Si and single-sided

Ground power station

TOPCon

Distributed

TOPCon

21.43

Bifacial

Distributed

TOP Con

22.3

Bifacial and double glass

Distributed

HJT

HJT half-cut cell, lead-free, gapless technology

21.7

Bifacial and double glass.

Distributed

TOPCon

22

Distributed

Bifacial and double glass

Distributed

TOPCon

HJT

MBB half-cut + high density encapsulation + non-destructive cutting

OTrend Force All Rights ReservedView entire presentation