Baran Group Meeting

Terry Lou

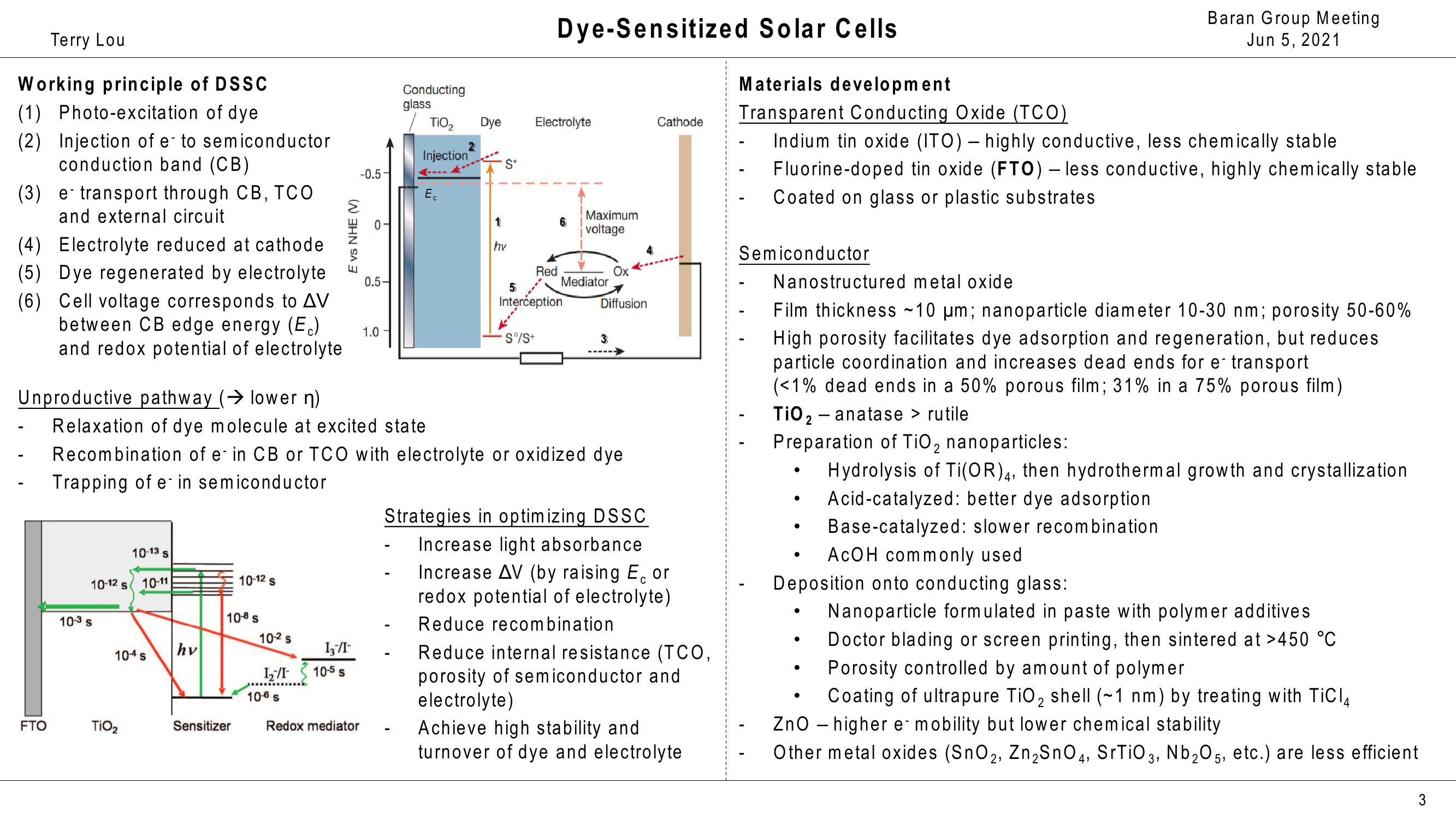

Working principle of DSSC

(1) Photo-excitation of dye

(2) Injection of e- to semiconductor

conduction band (CB)

(3) e-transport through CB, TCO

and external circuit

(4) Electrolyte reduced at cathode

(5) Dye regenerated by electrolyte

(6) Cell voltage corresponds to AV

between CB edge energy (Ec)

and redox potential of electrolyte

Unproductive pathway (→ lower n)

-

E vs NHE (V

-0.5-

Conducting

glass

TiO2

Injection

Ec

Dye-Sensitized Solar Cells

Dye

Electrolyte

Cathode

2

S*

1

6

Maximum

voltage

hv

Red

Ox

Mediator

5

Interception

Diffusion

1.0

S%/S+

3

0.5-

Relaxation of dye molecule at excited state

Recombination of e- in CB or TCO with electrolyte or oxidized dye

-

Trapping of e in semiconductor

10-3 s

10-13 s

10-12 s 10-11

10-12 s

10-8 s

10-2 s

hv

104 s

12/I-

10-6 s

13/I-

10-5 s

FTO

TiO2

Sensitizer

Redox mediator

Strategies in optimizing DSSC

-

C

Increase light absorbance

Increase AV (by raising Ę or

redox potential of electrolyte)

Reduce recombination

Reduce internal resistance (TCO,

porosity of semiconductor and

electrolyte)

Achieve high stability and

turnover of dye and electrolyte

Materials development

Transparent Conducting Oxide (TCO)

Baran Group Meeting

Jun 5, 2021

Indium tin oxide (ITO) – highly conductive, less chemically stable

Fluorine-doped tin oxide (FTO) - less conductive, highly chemically stable

Coated on glass or plastic substrates

Semiconductor

Nanostructured metal oxide

Film thickness ~10 μm; nanoparticle diameter 10-30 nm; porosity 50-60%

High porosity facilitates dye adsorption and regeneration, but reduces

particle coordination and increases dead ends for e- transport

(<1% dead ends in a 50% porous film; 31% in a 75% porous film)

TiO2 - anatase > rutile

Preparation of TiO 2 nanoparticles:

.

•

•

•

Hydrolysis of Ti(OR) 4, then hydrothermal growth and crystallization

Acid-catalyzed: better dye adsorption

Base-catalyzed: slower recombination

AcOH commonly used

Deposition onto conducting glass:

•

Nanoparticle formulated in paste with polymer additives

•

Doctor blading or screen printing, then sintered at >450 °C

•

Porosity controlled by amount of polymer

Coating of ultrapure TiO 2 shell (~1 nm) by treating with TiCl4

ZnO higher e mobility but lower chemical stability

Other metal oxides (SnO 2, Zn2SnO 4, SrTiO 3, Nb2O5, etc.) are less efficient

3View entire presentation